Drilling in the extremely deep waters of the US Gulf of Mexico has revealed huge oil reservoirs, and gaps in the industry’s capabilities.

While much attention has gone toward creating high-performance equipment to develop and produce oil from high-pressure/high-temperature (HP/HT) formations such as the Lower Tertiary, researchers around the world have been quietly working on measuring how oil behaves under those extreme conditions.

“New tools are needed to represent reservoir fluid properties at temperatures from subsea (~30°F) to the reservoir temperatures near 400°F and pressures ranges from ambient to 30,000 psi,” said Jefferson Creek, a senior research consultant at Chevron Energy Technology. “Developing numerical representations requires a solid base of appropriate measured data to benchmark performance of new equations or new procedures.”

A study organized and backed by the National Energy Technology Laboratory (NETL) of the United States Department of Energy first looked to see if any laboratory had tested how oil performs at really high pressures and temperatures.

“The bottom line is there are huge gaps in data in high-temperature reservoirs where they are already producing,” said Robert Enick, a research professor at the University of Pittsburgh, one of the lead researchers on the NETL project.

One reason for the gap was the lack of equipment capable of making those measurements and the obstacles facing anyone who wanted to build it. It is extremely tough to prevent leaks at those pressures, and the usual measurement methods do not work because sensors cannot survive at those temperatures. The devices they created to do the job showed that the formulas commonly used at lower temperatures and pressures are a poor fit once the temperature exceeds 300°F.

When commonly used models were used to extrapolate those properties under HP/HT conditions, density predictions were off by as much as 50%, and viscosity errors were as high as 75%, according to a project presentation. Based on multiple HP/HT density and viscosity tests of components that make up crude oil, equations were identified that offered a good correlation to the data. By tweaking some of the parameters in those equations it was possible to get a closer fit with the test results.

Now the results are being passed on to the large oil companies working in ultradeepwater.

“What I have found on talking to the oil companies is that everyone is very interested in the high-temperature/high-pressure data we are producing,” said Deepak Tapriyal, lead chemical scientist with URS Corp., a researcher on the project. “As we produce more data, they will use it to validate and/or improve their in-house models.”

HP/HT Hardware

To create HP/HT laboratory equipment, Mark McHugh, a professor at Virginia Commonwealth University, was brought in by NETL because he is an expert on how extraordinarily high pressures and temperatures affect polymer-fluid mixtures.

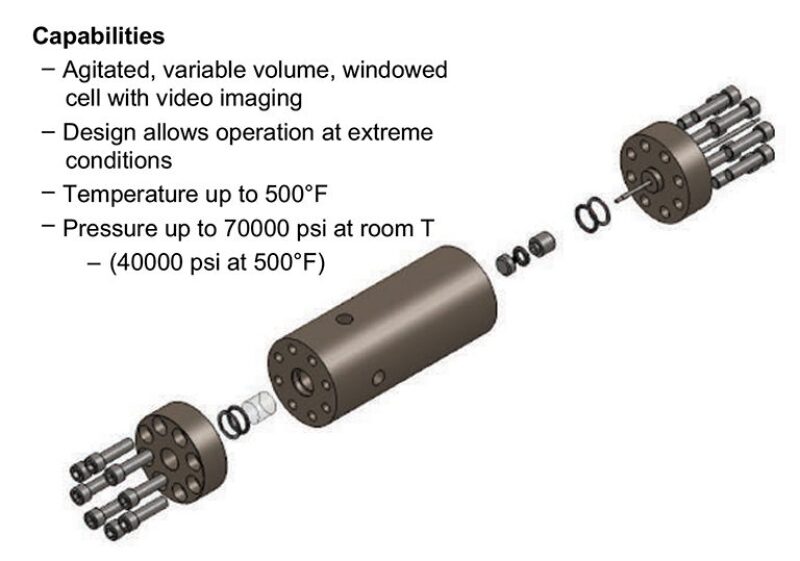

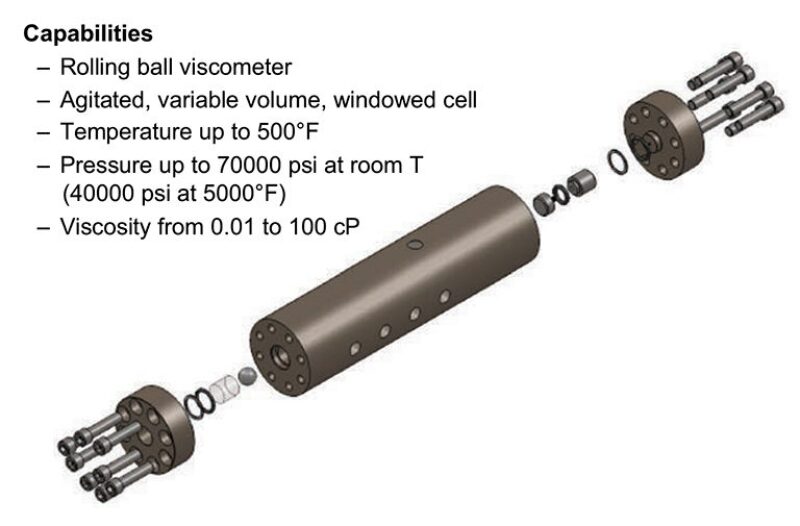

Two devices were built around a stout, hollowed-out cylinder made of Inconel, an alloy that is extremely strong and non-magnetic. It was closed in with end pieces bolted on using seals designed by McHugh that are resilient enough to stand up to extreme conditions during a test without leaking. Each device has windows made of sapphire for external observation.

The densimeter measures the density by observing the volume of a set amount of a compound at a designated pressure and temperature. The hydrocarbon is pressurized by a piston pushed by water. The volume of the sample is measured by how far the piston travels, the pressure based on the force used to push the piston, and the temperature measured by a thermocouple in the chamber wall whose tip sticks inside. A window allowed McHugh’s graduate students doing the tests to verify that the liquids were not solidifying.

Viscosity is measured using a rolling ball technique. While the approach is not new, this device designed by Hseen Baled, a graduate student at the University of Pittsburgh, is the first to include windows on the sides and at the end to allow direct observation of the ball moving, Enick said.

For the test, the tube is tilted to a fixed angle and a magnet used to release a pin holding an Inconel ball, which then rolls through the oil to the other end. The side windows are used to determine the ball velocity.

Conceptually, it works like the sensors on an automatic garage door that react when the beam is broken by someone walking past. The speed of the ball is measured by timing how long it breaks a beam of light traveling from a source outside a sapphire window that is aimed at a sensor behind the window on the opposite side. The ball’s velocity and the fluid density are used to calculate viscosity.

Testing began with single components, such as octane, pentane, and xylene, and has included two-component mixtures. The goal is to gather data on significant components found in crude oil so they can be used to estimate the properties of a wide range of crude oils.

With data in hand, Enick described the next step as “the fun part”: comparing the actual data with predictions by widely used models for those high-pressure and temperature levels. The most accurate have not been around as long as some of the most widely used formulas, Enick said.

No model for density was perfect but some were close and, with modification, could generate findings close to the test results. There were two finalists identified and modified by Ward Burgess, a researcher at NETL: a HP/HT version of a volume-translated Peng-Robinson equation, and a HP/HT version of the PC SAFT equation.

Two reliable options were found for viscosity: The free volume theory used in conjunction with either density model, or the friction theory.