Every process plant presents a high number and diversity of valves that control the flow of feedstock, products, and service liquids and gases. A comprehensive program was developed for a major US refinery to assess the musculoskeletal risk associated with manually operated valves then to rank each valve according to the risk each poses to plant operators and maintenance technicians. Valve repair and replacement is expensive, so the cost-effective approach was to assess only those valves that are critical to plant operation.

Introduction

Process plants contain a large number of process valves with a wide diversity of designs that control the flow of a wide range of fluids. The ergonomic issues associated with the design, operation, and maintenance of valves include

- Physical stress to open and close them

- Potential for injuries and subsequent related costs

- Lack of access to process-critical valves

- Difficulty of removing and replacing them

- Potential for process upsets when valves cannot be operated in the time required

As a result of injuries suffered while operating valves, a major US petroleum-refinery company initiated a program to identify high-risk valves and to modify them to reduce the operating risk of injury.

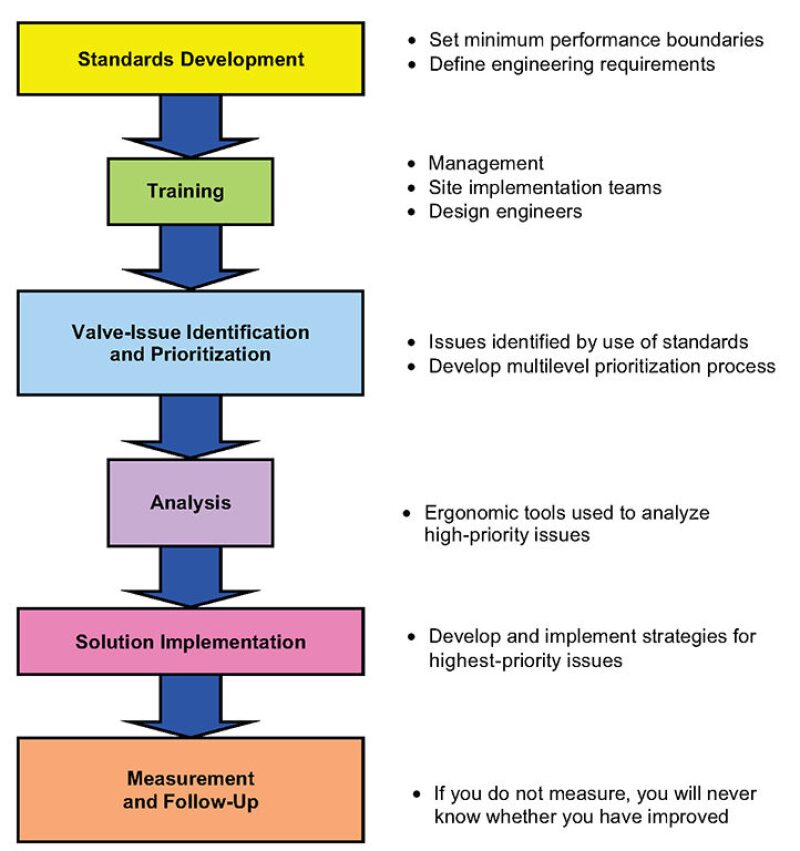

A model, illustrated in Fig. 1, was developed to create a systematic approach to identify the valve issues in a process plant, analyze the issues, prioritize the valves that need attention, implement a solution, and measure the results. The approach can be modified to reflect the unique character of the plant that implements the program.

The objectives of the study were to

- Develop a valve-risk-assessment program unique to the process plant based on the plant’s human-factors engineering-design standards and the valve-assessment model.

- Assist site personnel in identifying the process-significant valves and surveying them to determine the top candidates for repair or replacement.

Process-significant valves were those that met the following definitions:

- Frequently operated—valves that are operated more than four times per year

- Operated in an emergency—emergency block valves, emergency isolation valves, battery-limit valves, depressuring valves, and dump valves

- Manual, gear-operated valves

- Large valves—valves with valve wheels ≥24 in. in diameter

- Manual block valves and bypass valves around control valves

Method

A systematic approach was used to identify and assess the operations and maintenance issues associated with process-significant valves within the refinery. The approach consisted of the following eight distinct activities:

- Develop plant standards for human-factors requirements in the design, operation, and maintenance of valves.

- Train a group of refinery personnel consisting of operators; maintenance technicians; plant engineers; and safety, health, and environment staff in ergonomic issues associated with valve operations and maintenance.

- Lead the group in developing the definition of process-significant valves.

- Identify the valves that meet the definition in each unit of the refinery.

- Assist refinery personnel in defining the characteristics of valves that determine their risk of personnel injury or their potential for causing process upsets.

- Develop a quantitative scale for each of those characteristics.

- Field assess each of the process-significant valves against the characteristics.

- Calculate the sum of the risk characteristics for each valve, and develop a risk-prioritization ranking list; this will permit the refinery to repair or replace valves, as business conditions permit, according to their position in the ranking list.

The characteristics that were identified to assess the risk of valve operation are related to

- Whether the valve has already contributed to a musculoskeletal injury

- Musculoskeletal stress disorders, namely

- posture

- force (both steady state and initial)

- frequency

- Time required to operate the valve

- Adequate hand clearance between the valve and other valves or structures

Most of the characteristics are based on the valve-design standards that were developed for the company.

Once refinery personnel were trained on the risk characteristics of valves, they were asked to identify each valve in their unit that met the definition of “process significant.” Once each unit’s list was complete, forms were used by unit operators to field assess each listed valve and record the results for analysis. The data from each form were entered into a spreadsheet to calculate a risk index for the valve. Each question from the forms was assigned a score. The risk index for a particular valve was the total of the individual scores from each question.

The team was also trained in the field assessment of each valve. The assessment involved measuring the rim force required to turn the valve and determining the location and orientation of the valve and any access obstructions.

Results

Data for 44 valves were collected and submitted for analysis.

High-Risk Valves. The five valves with the highest risk scores have the following common features:

- Each requires the application of rim force exceeding 80 lbf to crack open the valve.

- With one exception, each requires the application of more than 80 lbf to turn the valve continuously (steady state).

- With one exception, each requires excessive force (in excess of 120 lbf).

- With one exception, each has less than 3 in. of clearance from an adjacent structure.

The valve with the highest risk score is shown in Fig. 2.

Low-Risk Valves. The valve that has the lowest risk score (i.e., exhibited the least risk of injury) has the following characteristics (Fig. 3):

- Each had not contributed to an injury.

- Each has a maximum rim cracking force of approximately 65 lbf and a steady-state operating rim force of approximately 60 lbf.

- Each is located and oriented in an almost ideal spot for operating.

- Only one valve has time-critical operation and high turn frequency, but this valve also has one of the lowest cracking and steady-state forces.

- Each has good hand clearance from other valves or structures.

Discussion and Recommendations

The data collected and analyzed in a field operating environment support the methodology employed.

Each of the high-risk valves identified in this study is difficult to crack open and operate in steady state. The most effective intervention for this group of valves is to service them to reduce the rim force required to operate the valves and, subsequently, maintain them so the rim force remains low.

Some high-risk valves were either poorly placed or obstructed, making them hard to reach. Research shows that, when valve locations and orientations result in poor posture, they increase musculoskeletal risk even if the valve rim force is not excessive. Potential improvements for those valves were more varied and specific to the situation.

The mounting heights of many high-risk valves were either too high or too low. In three examples, the valve wheels were located below the operator’s platform; they required the operator to access the valve handle through a slot cut into the platform.

Some of the 15 valves reported in detail have handwheels with enough clearance to accept a slightly larger actuator. Larger actuators provide users with more leverage and allow them to apply more torque to the valve stem. However, available clearance is minimal and an increase in actuator diameter of no more than an inch or two is recommended.

In several cases, the most effective method to overcome high rim force or to meet time constraints on opening or closing the valve is the use of a portable, powered valve-turning tool, of which there are several available commercially.

Finally, it is recommended that each valve that is modified to improve access or reduce rim force be re-evaluated by use of this evaluation program. Re-evaluation will confirm whether the modifications that were intended to improve valve operation did, in fact, do so.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper SPE 165690, “A Method for Ranking the Musculoskeletal Risk of Operating Valves in Process Industries,” by Dennis A. Attwood, Human Factors Applications, and Alicia T. Tys, Marathon, prepared for the 2013 SPE Eastern Regional Meeting, Pittsburgh, Pennsylvania, USA, 20–22 August. The paper has not been peer reviewed.