Nearly 2 decades after it was dreamed up as a way to do the job of two icebreakers with just a single hull, the oblique icebreaker has been launched into service in the Gulf of Finland. The Baltika, a first-of-its-kind vessel, completed sea trials in March and despite it launching too late in the season to work in heavy ice conditions, it will nonetheless provide a basis of understanding for the future development of such vessels.

The idea for an oblique icebreaker was born in 1996 from an internal innovation contest at the Helsinki-based engineering firm Aker Arctic, a company that has designed 60% of the icebreakers operating today. Contest entries were trying to solve the problem of how to best escort Aframax crude tankers through the Gulf of Finland in the Baltic Sea during ice season from Russian export terminals in Primorsk. The tankers needing ice escort from Primorsk are 42 m to 44 m in breadth, but the typical beam of a conventional ice breaker is between 20 m and 26 m. “That meant you had to have at least two icebreakers to assist one vessel,” said Arto Uuskallio, sales and marketing manager of Aker Arctic.

By using an icebreaker capable of operating in a sideways fashion, Aker Arctic realized that it would need just one icebreaker to cut a channel wide enough for the tankers to sail through safely. A distinguishing feature of the Aker ARC 100 is the vessel’s asymmetric hull, which is a stark contrast to conventional ocean-going vessel designs. The symmetrical geometric arrangement of conventional vessels makes it easier for the ship designer to arrange the loads inside the vessel and on the deck. “With this kind of vessel, you have to pay more attention to your weight distribution so that you can balance it with your ballast,” Uuskallio said.

To achieve what Aker Arctic refers to as “course stability,” the vessel relies upon a computerized autopilot to control its three azimuth propulsion units. “It is like a multipurpose tool,” he said, noting that the vessel can be operated forwards, backwards, sideways, and at other angles. “There are some maneuvers that we have already figured out, but the captains will find out the many other things they can do with the vessel as they operate it.”

After the Finnish government expressed interest in ordering oil spill collection vessels for its territorial waters, Aker Arctic added an oil recovery system to the oblique icebreaker. The difference between the oblique icebreaker and conventional vessels with oil spill recovery systems is that almost all those vessels rely on booms to collect the oil. The downside of the booms is that in heavier seas, waves can push the oily water over the boom, decreasing the efficiency of recovery efforts. In contrast, as the oblique icebreaker moves sideways, “the main oil boom is the vessel itself,” Uuskallio said. “So we can operate in more difficult sea conditions and higher wave heights, because the waves won’t go over the vessel and so it can collect more oil.”

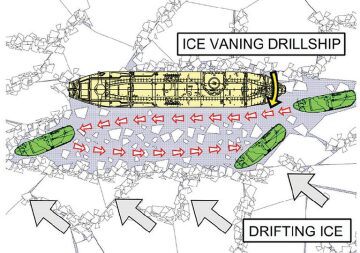

The company already has designs for an Arctic version of the oblique icebreaker that would be capable of supporting offshore drilling operations. The Arctic oblique icebreaker is designed to be twice as powerful as the Baltic version, while other features can be tailored to meet the needs of the operator. “The Arctic is a big region, where ice and sea conditions vary significantly from area to area,” Uuskallio said. “The final ideas and practices of how to actually break the ice will come from the operators when they are using it in different ice conditions.”