A reservoir-monitoring system has been installed on a medium-heavy-oil onshore field in the context of redevelopment by gravity-assisted steamflood. The challenge was to monitor the lateral and vertical expansion of the steam chest continuously with seismic reflection. The high sensitivity of the buried acquisition system allows the tracking and monitoring of very small variations of the reservoir’s physical properties in both the spatial and calendar domains. A daily 4D “movie” of the changes allows proposing a scenario that explains the unexpected behavior of the production.

Introduction

The Schoonebeek field is in the northeast of the Netherlands with 1 billion bbl of stock-tank oil initially in place. Between 1948 and 1996, the oil was produced with several small-scale thermal enhanced-oil-recovery pilots with vertical wells. Today, the oil is produced by gravity-assisted steamdrive.

A permanent seismic system including 2D and 3D phases was installed in 2010 to monitor the reservoir’s evolution during steam injection. The monitoring lasted 2 years. During this time, the propagation of the steam plume injected into a horizontal well located between two horizontal producer wells was tracked in order to understand the 4D behavior of the steam and possibly update the dynamic production model.

Gravity-Assisted Steamdrive

Reservoir engineers are interested in knowing how the steam spreads from the injector to the neighboring producers. The pump rate then could be adjusted to optimize reservoir production.

The steam, injected at low pressure, is expected to rise to the top of the reservoir, then to spread horizontally, and finally to condense. Hot water will descend through the reservoir, heating the oil and improving its mobility.

A feasibility study was conducted by modeling the acoustic response of the pressure during cold production and steam injection. During the early steam-injection phase, pressure, temperature, and steam-zone thickness should change, but in different ways.

- The pressure changes should propagate quickly over the reservoir and will be nearly the same over the vertical dimension of the reservoir.

- The steam zone should initially be thin and should propagate horizontally along the top of the reservoir.

- The associated temperature increase should be near the top of the reservoir first and then increase vertically below the steam zone.

2D- and 3D-Seismic Monitoring

A permanent buried installation ensures excellent seismic repeatability and has a minimum effect on the local agricultural activities and the environment (Fig. 1 above). First, in December 2010, a 2D pilot survey was conducted. Second, in April 2012, the permanent seismic-acquisition geometry was extended to three dimensions.

The 3D system consists of 36 piezoelectric minivibrators placed into cemented boreholes 250 m deep. The signal was recorded by a set of five lines, each made of 69 dual-depth buried hydrophones at 6 and 9 m. The equipment is located above one horizontal injector and two horizontal producers. There are also two deviated observation wells measuring the temperature and pressure at two locations inside the reservoir. The sources vibrated simultaneously and continuously during the 2-year acquisition period. The 3D acquisition covers a subsurface imaging area of 800×120 m.

Three types of unwanted waves interfere with the reservoir reflections: the S/P wave converted at the surface, the source ghosts, and the receiver ghosts. Minimization of these unwanted waves is necessary to ensure an accurate recovery of the seismic monitoring results.

A processing sequence has been executed on a daily basis to provide migrated seismic cubes and 4D attributes. The processing workflow consists of

- Receiver ghost reduction by dual-depth hydrophone combinations

- Source ghost separation in the calendar domain

- S/P converted wave mitigation by separation in the calendar domain, plus a high-resolution 3D radon filter to remove residual linear waves

- Weekly sliding median filter in the calendar domain to remove remaining industrial noise

- Post-stack migration with a constant velocity to focalize the diffracted events

- Daily 4D-attributes computation; obtaining amplitude and travel-time variations by cross correlation with a reference

The repeatability improvement brought by the processing can be represented as the reduction of both amplitude and travel-time variations above the reservoir. Both the source and the receiver deghosting improve repeatability dramatically.

4D Monitoring Results

For both the 2D- and 3D-seismic monitoring, the daily 4D attributes are obtained by use of a trace-by-trace cross correlation with a reference data set. The lengths of the correlation windows are 100 and 20 ms for the travel times and the amplitudes, respectively. The 4D attributes are then compared with actual well information. At the injector, the seismic attributes are compared with the steam-injection rate.

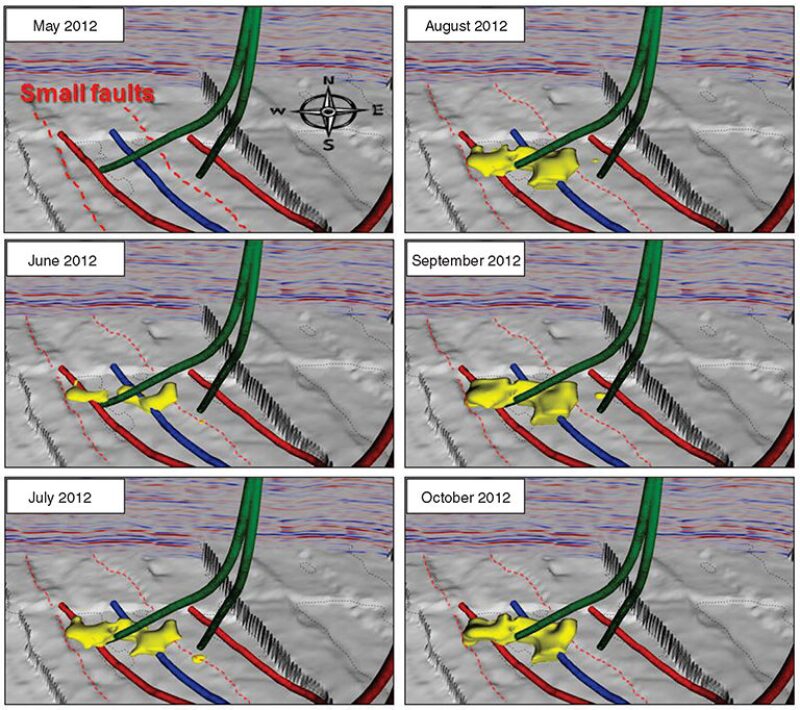

The 3D monitoring system is required to understand and map the complex path of the steam propagation following the injection period. To visualize the daily evolution of the amplitude variations, a 4D movie was produced.

Fig. 2 shows snapshots of the 4D movie computed during the injection. The 3D yellow blob is the amplitude variation compared with conditions in May 2012. It represents the spatial and calendar amplitude spreading from steam injection.

The amplitude variations obtained by cross correlation give a cumulative effect of the steam over the whole reservoir thickness but do not allow for distinguishing the 4D effects between the top and the base of the reservoir. To investigate what happens inside the reservoir, a 4D acoustic inversion has been conducted on a monthly basis. The stratigraphic inversion allows a better vertical resolution.

Although the quantification of 4D effects in terms of P-impedance variations was in agreement with the petroelastic model, the very low seismic fold with a limited offset range restricted the 4D inversion to only the estimation of the acoustic P-impedance variations. But the P-impedance variations alone are insufficient to understand the complex rock-physics phenomena that occur during steam propagation.

The next step would be the quantitative validation of the P-impedance variations and the interpretation of their evolution in terms of fluid or temperature variations because they occur in different ways over the days. To do so, the plan is to use additional constraints coming from the petroelastic model and take advantage of the high resolution in the calendar domain.

Conclusion

The precision and stability of the permanent and continuous buried acquisition system allowed for the detection of both small travel-time and small amplitude variations over 2 years. The accuracy of these values is confirmed by measurements made at observation wells.

The deployment of the 3D survey allowed investigation of the complex path of the steam from the injector to the producer, providing valuable information to build more-accurate dynamic models for better reservoir-management decisions.

The benefit of the 4D acoustic-inversion trial conducted on this data set is the vertical resolution that is used to differentiate P-wave-impedance variations between the top and base of the reservoir.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper SPE 165428, “Continuous Land Seismic Reservoir Monitoring of Thermal EOR in the Netherlands,” by Julien Cotton, Laurene Michou, and Eric Forgues, CGG, and Kees Hornman, Shell Global Solutions International, prepared for the 2013 SPE Heavy Oil Conference Canada, Calgary, 11–13 June. The paper has not been peer reviewed.