What gave rise to oil drilling in the Permian Basin—in particular the Spraberry trend area? Why now the focus on the various Wolfcamp plays? What strategies and techniques have proven useful in exploiting the potential of the Spraberry—and now, of the Wolfcamp source rock? Who are some of the players, where are they buying, where are they holding leases or developing them—and how?

According to J. Michael Party, vice president for Exploration Reliance Energy, writing in the May 2012 AAPG Explorer, “The early exploration efforts in the Permian Basin started in Mitchell County on the basin’s eastern shelf, with a 10-barrel-a-day well [the W.H. Abrams No. 1 well] that opened the Westbrook field in 1920. This set off a frenzy of activity in the basin,” due in large part to the availability of inexpensive leases from the University of Texas Land System.

The true potential of the prolific and problematic Permian Basin, however, was not evident until the Santa Rita #1 well erupted on 28 May 1923. Spudded at a place called Texon in Reagan County, Texas, the project endured 21 months of cable-tool drilling that averaged less than 5 ft a day. After the Texon Oil and Land Company struck oil, the well produced until May 1990, and was named by Texas Monthly Magazine as the “Oil Well of the Century.”

This field, which came to be known as Big Lake, proved to be 4.5 sq miles. Its wells revealed that vast oil reserves in west Texas originated in both shallow and deep horizons.

The Westbrook and Big Lake field successes were followed by a series of discoveries, including the World and McCarney fields in 1925 and the Yates field in 1926. In 1928, a Big Lake well was drilled deeper than any in the world up to that time, to a depth of 8,525 ft.

According to the Texas State Historical Association (TSHA), before the Hobbs field discovery in 1928, all Permian Basin discoveries were made as a result of random drilling or surface mapping using Cretaceous outcrops that could give indication where structures were in the subsurface. “The Hobbs field discovery,” states the TSHA, “was made after magnetometer and torsion balance surveys both showed the area to be anomalous.”

As more wells were drilled in the area, subsurface mapping became better defined. The Wasson and Slaughter fields were discovered in 1937. Although first drilled in 1938, the first discovery in the Kelly Snyder field was not made until 1948.

Commercial drilling did not start in the Spraberry trend area until January 1948. Essential to its success would be a new technology dubbed “Hydrafracking,” introduced by Stanolind Oil and Gas Corporation (Amoco) in the Hugoton gas field in Grant County, Kansas, in 1947, with the first two commercial Hydrafrac stimulations performed by the Halliburton Oil Well Cementing Company in Stephens County, Oklahoma, and Archer County, Texas, on 17 March 1949.

The Spraberry: Key to Today’s Rise in Permian Basin Oil Production

The Wasson has the highest cumulative oil production of any field in the Permian Basin, with more than 2 billion bbl over its lifetime. Second is the Yates field, with more than 1.4 billion bbl of cumulative oil production; third is the Kelly-Snyder field with almost 1.4 billion bbl; and fourth is the Slaughter with slightly less than the Kelly-Snyder field.

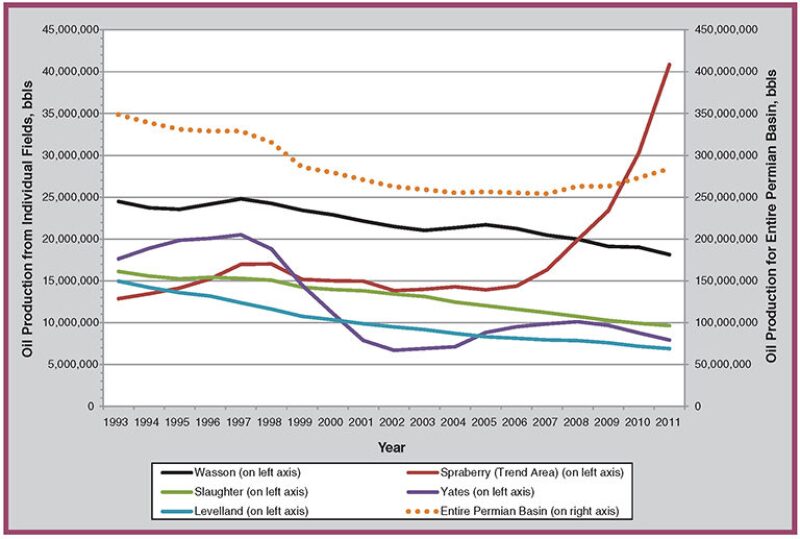

However, it is the fifth-highest-producing area, the Spraberry trend area, with about 1.13 billion bbl of cumulative oil production, that is receiving the greatest attention today. The Spraberry is the only field among the Permian Basin’s top 10 that in recent years does not show either a downward or flat trend in annual oil production (Fig. 2). From 1993 to 2005, Spraberry annual oil production hovered a little above or below 15 million bbl per year, but—in marked contrast to other Permian Basin fields—in 2006 it began a steep continuous rise to 41 million bbl in 2011.

According to the Railroad Commission of Texas, to date, the Permian Basin has produced around 30 billion bbl of oil and 75 Tcf of gas and “it is estimated by industry experts to contain recoverable oil and natural gas resources exceeding what has been produced over the last 90 years.”

Annual oil production from the basin climbed from 251 million bbl in 2007 to 282 million bbl in 2011. The vast majority of the increase originates in the Spraberry trend. Plumbing its proved reserves is key to the 60% rise in crude oil production in the Permian Basin to at least 1.82 million BOPD predicted to occur by the end of 2016, according to Colorado-based energy consultancy Bentek. In August 2012, Bentek estimated then-current Permian Basin oil production at 1.29 million BOPD.

The Spraberry’s Initial Boom

What has attracted people over the years to the Spraberry is the sheer size and extent of its original oil in place. A great deal of human ingenuity has been used in the quest to get at those resources—primary among them being hydraulic fracturing, waterflooding, and CO2 injection.

According to Roger M. Olien and Diana Davids Hinton in Wildcatters: Texas Independent Oilmen, “A large independent, the Seaboard Oil Co., made the first Spraberry discovery in 1943, but did not establish commercial production until January 1949, when its well, Lee No. 2-D, flowed 319 barrels per day after being shot with nitroglycerin. During February 1949, Arthur ‘Tex’ Harvey, an east Texas wildcatter, found oil in the same formation, some 65 miles to the south of Seaboard’s well. Later in the month the Hunt interests of Dallas discovered Spraberry oil to the north, in Borden County. These three discoveries were overshadowed by the more sensational discoveries in Scurry County until 1950, when the limits on most of the Canyon Reef reservoirs were clearly defined.”

A sequence of discoveries in 1950 stimulated revitalized interest in the Spraberry trend. “As the extent of the trend was defined by these discoveries,” write Olien and Hinton, “a tremendous drilling boom was under way by 1951.” After a few months of rapid development, however, developers found that many Spraberry wells declined quickly from their impressive initial production, after which they “had to be pumped to secure even a scant amount of oil.”

“As additional data accumulated, it became clear that the high expectations of production from the Spraberry trend would have to be significantly revised. The irregular vertical fractures of the formation presented formidable problems for reservoir engineers. The Spraberry sand itself, moreover, was exceptionally tight; operators resorted to shooting [nitroglycerin] and the more recently developed technique of hydrofracturing to stimulate production.”

During 1952, according to Oilien and Hinton, production data continued to fill out a discouraging profile of Spraberry performance. With the sharp drop of the pressure of the natural gas present in the formation, production in many parts of the trend went into precipitous decline. Those operators with enough financing to do so often resorted to hydrofracturing, in effect making it easier for oil to flow through the tight formation, but this step did not reverse the decline of production for long. No easy solution was found to the Spraberry production problems. In 3 brief years the whole trend went from ‘America’s giant oil field’ to its local designation as the world’s largest unrecoverable oil reserve.

Coddling Spraberry Wells

A Time magazine article 8 October 1951 cites the booming Spraberry trend. “Like [wildcatter] Tex Harvey, other drillers have found that a Spraberry well must be coddled. Because of the hard-packed nature of the formation, ordinary drilling methods will not release the oil; instead, a gelatinous compound of soap and kerosene, followed by coarse sand, must be pumped into the hole under tremendous pressure. This loosens the fractures and the oil begins to flow freely.” The author is, of course, referring to ‘hydrafracking.’

“Contrary to the conventional wisdom of wildcatting,” says the Time article, “in Spraberry getting in early meant coping with unforeseen difficulties rather than reaping bonanza profits—yet Spraberry had seemed as close to a sure thing as the oil industry ever encounters.” With natural production declines and a well shut-in ordered by the Railroad Commission of Texas, there were some “oilmen [who] dubbed the Spraberry trend the graveyard of the oilman’s hopes.”

“If Spraberry offers graphic illustration of both general and local problems affecting independents,” write Olien and Hinton, “its history after 1953 provides examples of how some operators successfully adapted to its unusual and discouraging conditions. Prominent among the successful operators were those who were in a position to exploit technological progress to increase production. Improved fracturing techniques later enhanced oil recovery; improved drilling muds and more efficient casing programs cut the cost of wells by one quarter. In all later entrants realized greater gains because of improved drilling and completion techniques, both of which lowered costs.”

“In the Spraberry trend,” the authors continue, “the scientific data the majors had gathered while drilling wells were indispensable to enhancing production after oil was found, and the majors had the scientific staff ready to put those data to use. By contrast, many small independents active in the Spraberry were more interested in promotion than in science, and they lacked the assets to take on projects with high initial costs and slow payouts.”

The Rise of Easier Foreign Oil — and Secondary Recovery

According to Olien and Hinton, in the early to mid-1950s, producers in the US were facing areas like the “stubborn Spraberry trend” where they “tried every device they could to wring oil and profits” from them. It seemed “there was an economical alternative to coping with the increasingly complex problems of domestic oil operations, that of finding and developing oil fields overseas and importing production and products. When the cost of producing a barrel of American oil averaged 70 cents in 1948, the cost of producing a barrel of Saudi Arabian oil averaged only 20 cents, according to one estimate.”

“Middle East prospecting after World War II brought in incredibly rich oil fields,” write Olien and Hinton. “Domestic discoveries during the same period, though numerous, were for the most part unspectacular. By 1954, the average new Saudi well could be expected to produce for 20 or 30 years.”

By 1960, the world was experiencing an oil glut. The Railroad Commission of Texas, which oversaw one-third of US output, limited production on conventional, primary-recovery wells. There were fears that secondary-recovery efforts would be so successful that their production should be subjected to the same limits as primary-recovery wells.

A Time magazine article on 18 July 1960, states “In the past 10 years secondary-recovery operations have increased sixfold, though they still account for only 5% of Texas’ 80-million-bbl monthly output.”

The focus of this plan to start secondary-recovery efforts was the giant Spraberry trend. The Time article names waterflooding, fireflooding, and miscible-phase displacement. “So far,” the article states, “15 billion bbl of oil have been pumped out of Texas fields by primary methods, and primary means can recover another 15 billion bbl. Another 10 billion bbl can recovered by secondary methods currently in use. Still remaining in the ground, however, will be another 50 billion bbl.”

Waterflooding in the Spraberry

Gradually, over the decades, understanding of the Spraberry trend grew. By 2001, the authors of paper SPE 71635, Development of a Fracture Model for Spraberry Field, Texas USA, summarize the history of the Spraberry to that point: “At the time of its discovery in 1949 the Spraberry trend was considered the largest oil field in the world. The original primary recovery factor was anticipated to be less than 10%.

“In an effort to increase recovery, several areas of Spraberry were placed on waterflood beginning in the late 1950s. Waterflooding, for the most part, has been only moderately successful. The noted exception to this is the waterflood performance on the E.T. O’Daniel lease. The waterflood recovery in this lease has exceeded 25% of the original oil in place.

“Failure of waterflooding in Spraberry has been attributed to the low matrix permeability and extensive fracturing. Many studies have been conducted to understand the Spraberry fracture characteristics. However, the characteristics of the fracture network and its interaction with the supporting matrix framework remains poorly understood.”

A Challenge From Day One

In the September 1967 issue of JPT, author George M. Guidroz of Mobil Oil, discusses the E.T. O’Daniel Project—A Successful Spraberry Flood: “The Upper Spraberry zone on Mobil Oil Corp.’s 2,160-acre E.T. O’Daniel lease has been under waterflood since August 7, 1959.”

Guidroz goes on to remind readers that “The Spraberry trend area field proved to be unique among oil-producing reservoirs almost from the day of its discovery. This vast reservoir has challenged the industry’s ingenuity under both primary and secondary recovery operations.”

By 1977, the Spraberry’s fortunes seem to have changed, however. In paper SPE 6449, published in 1977, Tom Dougherty of Petroleum Information Corporation, discusses US Drilling—Who, Where, Why, and How Deep. He states, “It has already been noted that development drilling has been increased significantly since 1975. The 10 leading fields in the United States for 1973 are shown [in a list]. Of particular interest to Permian Basin observers is the fact that the Spraberry ranks fifth on this list but was first on the 1975 list. Perhaps either ranking might be surprising until it is recalled that economic conditions have changed drastically enough to make the formerly uneconomic Spraberry development attractive.”

Hydraulic Fracturing and Horizontal Wells

The insight to combine horizontal drilling with hydraulic fracturing still was not clear in 1987 and the two techniques were rather seen as competing against each other. In paper SPE 16868, author S.D. Joshi of Phillips Petroleum, writes “A horizontal well offers a viable completion option and will compete with fracturing in the future.”

Joshi states, “The technology to drill and complete horizontal wells is available. Horizontal wells and drainholes can be looked upon as infinite conductivity fractures. In the future, in many situations fracturing and horizontal well technology will compete with each other. The technology to stimulate horizontal wells is being developed.”

The following year, a horizontal well was drilled in the Spraberry trend—and was hydraulically fractured. Paper SPE 19721, Drilling and Completion of a Horizontal Lower Spraberry Well Including Multiple Hydraulic Fracture Treatments, by C.W. White, of Mobil E&P US, is terse and highly technical. However, its description of the John Snowden Well No. 7 as a “multiply hydraulic fractured horizontal Lower Spraberry well” sounds remarkably modern, as does its description of the vertical well: “A typical vertical well in the Spraberrry Trend will be commingled in the Upper Spraberry, Lower Spraberry, and the Dean Wolfcamp formations. All three formations require fracture treatments.” This could describe a 2013 vertical well.

The 1989 paper goes on to say, “The John Snowden #7 was completed in the Lower Spraberry formation alone. Other operators had drilled horizontal wells in the Spraberry Trend. The Snowden #7 was the first to have a liner cemented in place and individual and water fracture stimulations in five separate intervals of the horizontal hole.”

The author states that the three objectives of the well were:

- Higher initial production.

- Lower decline rate.

- Higher cumulative oil production compared to a typical vertical well.

These objectives, according to the paper, were to be achieved by creating five propped hydraulic fractures in a radiator fashion perpendicular to the horizontal hole.

The paper’s conclusions are perfunctory and technical. No sense is given of the relative significance of the achievement described in the paper—what may very well be among the first hydraulically fractured horizontal wells.

By 1992, acid stimulations were being used in conjunction with horizontal wells in the Wolfcamp formation. In paper SPE 23948, published in 1992, the authors state “A great deal has been published in recent years regarding horizontal well technology. However, little has been published concerning high rate acid stimulation treatments in openhole sections in horizontal wells.”

The authors describe The Keystone Cattle Company Well No. 378-H, located in Winkler County, Texas, which was completed in the Wolfcamp formation of the Flying ‘W’ field. The completion interval consisted of 1,388 ft of lateral, openhole section. A 200,000-gal multiple stage, foamed nitrogen acid stimulation was performed using polymer gel blocks for diversion.

The authors state further, “Ten vertical wells had been completed in the Wolfcamp formation before 1989, when the first horizontal well was drilled. Three horizontal wells have been completed in the field since 1989.”

In paper SPE 21260, published in 1990 and titled Practical Aspects of Horizontal Well Technology: A Perspective, U. Ahmed and S. Jacobsen of Schlumberger write, “With the recent surge in horizontal well drilling, increased attention has been focused on the application of technology to maximize well productivity. Application of horizontal wells to enhance hydrocarbon recovery is not new. Examples of horizontal well application date back to the early 1940s. In the past decade, improvements in drilling technology have renewed interest in horizontal wells. Concurrently, new technology in the area of formation evaluation, well performance, completion, testing, and stimulation have been introduced. Success has been mixed.”

He goes on to write, “Success of hydraulic fractures in horizontal wells depends on their orientation, reach, and fluid conductivity.” A few paragraphs later he states, “The final analysis must ensure that the planned horizontal well will surpass the performance of an equivalent stimulated vertical well and pay back the extra drilling and stimulation costs.”

While still subject to skepticism and in their early days, stimulated horizontal wells were on their way to becoming the norm.

Rehashing History Once Again

The skepticism regarding fractured horizontal wells would take awhile to overcome as the technique became better understood—and the choice would still often be seen as being between a hydraulically fractured vertical well and a nonhydraulically fractured horizontal well. Paper SPE 23949, published in 1992, is titled Evaluating Horizontal Well Potential in the Spraberry Trend. The authors write, “Eight attempts have been made to drill and complete horizontal wells in the Spraberry trend of west Texas. The results have been disappointing to date.”

They go on to state “The Spraberry trend of west Texas has been the target of extensive drilling since its discovery in 1949. Early wells in the trend were characterized by high initial flow rates after small stimulation treatments. The average initial potential from one study of 718 wells was 318 BOPD from open hole completions in the Upper Spraberry. The high initial potentials had sparked a boom in the early 1950s, where up to 203 rigs were running by mid-1951. The reservoir extent seemed enormous, with production established over an area 150 miles long and 50 miles wide. Operators were convinced they had found ‘a potentially great source of oil reserves.’”

“This boom was short-lived,” the authors write, “as the high potentials were accompanied by rapid decline. In three cases, wells produced from 26,000 to 40,000 BOPD in 15 to 17 months prior to abandonment. The poor success in sustaining economic production rates led operators to try different techniques to improve productivity. The two major techniques employed by operators were hydraulic fracturing and waterflooding.

“The earliest wells were openhole completed with a small cleanup ‘hydrafrac.’ A survey of 781 wells conducted in 1952 indicated that 92% of the wells in the survey were openhole completed, with the majority of the treatments consisting of 1,500 gal of fluid or less. As operators gained experience, the treatments increased to 4,500 gal of oil-based fluid carrying 2,400 lb of 20/40 sand. The treatments were generally pumped down 23/8-in. tubing at an average injection rate of 5 bbl/min.

“These early treatments did not limit the steep declines, and by 1954 operators began to implement treatments with higher rates and volumes. In a series of re-fracture treatments documented by Gerolde there were substantail improvements in productivity with larger job sizes. A typical re-fracture treatment consisted of 21,000 gal of frac fluid carrying 31,500 lb of 20/40 sand and 42 to 56 bbl/min down casing. Several wells that were producing less than 10 BOPD were increased to over 100 BOPD. One well recovered 55,438 BO in 34 months after a 4,500-gal fracture treatment. Prior to the re-fracture treatment the well was producing 1 BOPD. Following a re-fracture treatment consisting of 21,000 gal of oil-based fluid and 31,500 lb 20/40 sand the daily production rate increased to 333 BOPD and the well recovered an additional 34,155 BO in the next 18 months.

“In the period following the early ’50s, waterflooding gained popularity as a means to improve recoveries. The declines in production rates were accompanied by rapid declines in reservoir pressure, and waterflooding was considered a technique to reverse this decline in pressure and to sustain production. On 40-acre spacing the reservoir pressures declined 3.86 psi per day, while on 80-acre spacing the reservoir pressures declined 0.59 psi per day. Brownscombe and Dye (1952) suggested that oil could be displaced in the Spraberry by capillary imbibation of water into the rock. By 1953 it was suggested by Elkins that the low permeability matrix pores held the majority of the oil, and that the natural fractures provided flow channels for the oil to reach the wellbore. The concept of waterflooding the Spraberry was proposed to help limit the decline in reservoir pressure and to displace the oil in the matrix.”

Later, he writes, “By 1983 the estimated ultimate recovery from the Spraberry trend was 470 million barrels. The Bureau of Economic Geology estimated that this was only 5% of the estimated 9.4 billion barrels of oil in place. … On the revenue side, several operators believed that additional reserves could be recovered to improve the economics of the Spraberry/Dean by applying improved evaluation and completion techniques. The Bureau of Economic Geology reinforced this with several studies in the mid-1980s. With the growing interest in horizontal well technology in the mid-1980s, several operators saw horizontal wells as a means to improve recoveries. This was reinforced in a study of horizontal opportunities in Texas. The Spraberry/Dean was identified as a candidate for horizontal development, most likely due to its characterization as a naturally fractured reservoir with a low recovery efficiency.”

He states further, “When the wells were hydraulically fractured, high injection rates were necessary to prevent premature job screenouts.”

“The concept of drilling a horizontal well in the Spraberry trend was proposed as early as September 1951 by Legendre. He mentioned that one operator was planning a drainhole in the Spraberry, however any such early attempts went unrecorded in the literature. … By early 1985 the first horizontal test of the Dean was under way in Glasscock County.”

“Conclusion: None of the eight horizontal attempts have been economic successes. The horizontal attempts have helped confirm the orientation and conductivity of the natural fracture trend. The attempts have demonstrated the value of fully characterizing a reservoir prior to attempting an expensive completion effort. With the porosity-permeability relationship proposed in this study, a more complete characterization can now be made. An estimate can be made of vertical well productivity given various stimulation treatments, and the optimum completion design can be selected based on a rate of return criterion. An optimized vertical completion is recommended in lieu of horizontal completions in the Spraberry trend.”

But that same year, 1992, brought a more enlightened perspective.

In paper SPE 24322, titled An Analysis of Hydraulically Fractured Horizontal Wells, authors J.E. Brown of Dowell Schlumberger and M.J. Economides of Mining University Leoben, state “Horizontal wells with lengths up to 8,000 ft are capturing an ever-increasing share of all wells drilled. However, the performance of many of these wells is significantly less than what is predicted by published well performance models. The factors causing this variance must be understood if horizontal wells are to produce at their potential.

“Methods are presented in this paper that demonstate which reservoirs may benefit from horizontal wells instead of fractured vertical wells. Additionally, an extensive analysis of expected performance shows that many horizontal wells may also benefit from fracture stimulation, and that the vast majority of reservoirs that have traditionally been candidates for vertical well fracturing are obvious candidates for horizontal well fracturing.”

This was the true beginning of successfully combining the two techniques of hydraulic fracturing and horizontal drilling. And the Spraberry—later the Wolfcamp—played a big role in this development.

Permian Basin Wolfberry: Stimulation Evolution

In paper SPE 140724, titled Permian Basin Wolfberry: Stimulation Evolution and Economic Optimization, published in 2011 by Metcalf and Coronado of Baker Hughes, the authors state “Activity in the Wolfberry has recently increased, spurred by the current relatively strong oil prices. However the economic foundation of these producing wells is their stimulation and the management of completion costs.

“All of these wells require multistage fracture treatments to achieve economic production and therefore significant effort has been given to continuous improvement in efficiently completing and fracturing Wolfberry wells.’

The authors state that “The first true ‘Wolfberry’ wells were drilled in Upton County at the turn of the century by Henry Petroleum. The success of these wells brought upon a spread of ‘Wolfberry’ wells all across west Texas.”

The authors state “The Wolfcamp… can be difficult to ‘break down’ or initiate a fracture without the aid of acid. It has become common practice during cementing operations to displace the production casing string with acetic acid followed by water, typically 1,000 gal of 10% acetic acid. When the first stage of a Wolfberry completion is perforated the acetic acid will be ‘on spot’ or covering the perforations. The acetic acid helps clean up the perforation and initiate the fracture. The same ‘spotting’ of acid over the perforations is typically performed on subsequent Wolfberry stages by using hydrochloric acid during the flush portion of each fracture stimulation stage (not including the final stage). Typically 500 to 2,000 gal of 7.5% to 15% hydrochloric acid is used per stage. Once a fracture is initiated, the Wolfcamp fractures fairly easily.”

“The Spraberry has seen some changes in the number of fracture treatment stages from the typical three,” write the authors. “This is also the case for the single-stage fracture treatment of the Dean … for the years 2000 through 2005 [during which] the number of stages in the Wolfcamp has risen. Depending on the area the number of stages in a Wolfberry well in the last 5 years has varied from four to ten, … the average for 2010 being 8¾ stages per well. The number of stages varies as the operator decides how much vertical coverage he is getting per stage.”

The authors point out that “The Spraberry intervals are still being fracture treated with borate crosslinked guar gelled water systems today as they were in the early 2000s. These fluids range in polymer loadings from 15 to 20 lb per thousand gal of water (pptg). However the Wolfcamp intervals have seen a greater variety in fluids used over the last 10 years. Many wells have been fracture treated in these intervals using slickwater, others have used borate crosslink assist systems with 10 to 15 pptg of polymer and some have used linear gelled water systems using 10 to 20 pptg polymer loadings. Some operators are using a combination of these fluids to treat their wells.”