Almost a century after its first oil discovery, Argentina is making headlines again through reports of the potential of the Vaca Muerta Shale in the Neuquén Basin—the most prolific basin in Argentina (Fig. 1). The existence of Vaca Muerta, which means “dead cow,” has been known for years, but the formation received little attention until the development of shale plays in North America. Vaca Muerta is virtually a virgin play with only a few operators involved. Yet with Argentina’s need to increase production and reduce dependence on foreign oil and gas, change is clearly in the air.

Expanding Reserves and Production

YPF has reported reserves and resources in the Vaca Muerta formation to be an estimated 22.8 billion BOE (YPF 2012). Encouraged by the estimate, YPF and several other Argentinean operators are continuing exploration activity to define the extent and productivity of the Vaca Muerta, particularly to identify the oil, wet gas, and dry gas areas. Early results suggest that Argentina has an opportunity to replicate the unconventional resource revolution of the United States and eventually meet domestic oil and gas demand through internal production.

Argentina has the potential to increase oil and gas production by 50% in 10 years, which would reverse the negative trend that turned the country into a net importer in recent years. Yet this potential does not come easily, as preliminary estimates indicate the need for more than 1,000 wells to be drilled as a first step and 40 additional rigs to accomplish the goal. Besides the investment challenge that the Vaca Muerta now faces, there is an immediate challenge that needs to be dealt with: What is the best way to produce Vaca Muerta?

Maximizing Production in Shale, Other Tight Plays

In North America, the production of oil and gas from shale has increased greatly since 2007, with the development of several key plays such as the Bakken in North Dakota, the Barnett and Eagle Ford in Texas, and the Marcellus in the eastern United States, which have helped to reverse the declining production of the past few decades. The US and Canadian oil and gas industries were prepared for shale development. While these plays were not new to them, the use of new, unconventional exploitation technologies has been critical to success. In particular, as several studies have proved and is widely known in the industry, the challenge in these shale plays is connecting productive channels and creating fractures that will allow proper fluid movement and endure through the production cycles.

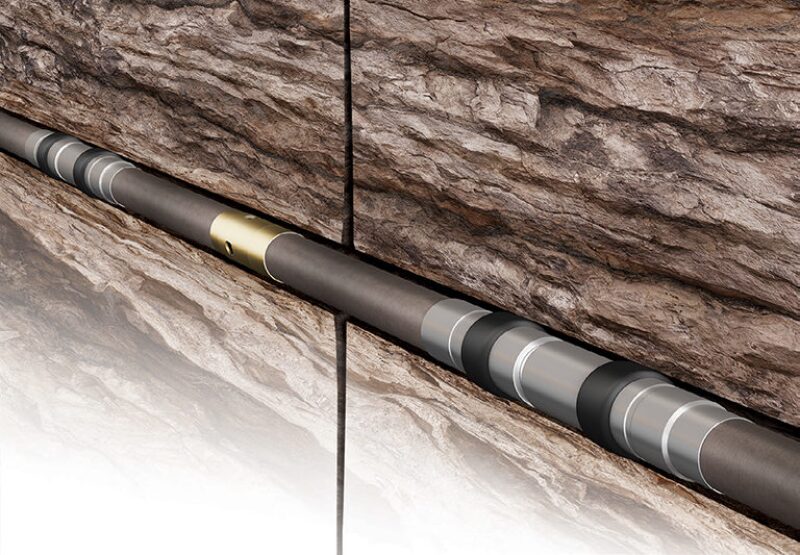

Openhole multistage hydraulic fracturing has been instrumental in developing oil and gas shale projects, of which the Bakken play has provided numerous examples.

Argentina and YPF have not been blind to the progress made in the US and Canadian shale plays. Since 2007, some of the technologies and methods used in North America have been successfully deployed in the Neuquén Basin. Argentina has used technology from the Bakken and similar shale plays to increase oil and gas production in the basin’s tight fields and formations.

One effective method has been based on the openhole, multistage fracturing systems used in the Bakken (Fig. 2). These systems enable continuous pumping operations and use high-performance openhole packers and ball-activated fracture ports to reduce operating time; lower cost; improve health, safety, and environmental protection capability; and maximize production. The production increases because openhole completions enable direct production from the entire horizontal pay zone, including natural fractures and induced fractures, vs. the conventional “plug and perf” cemented casing process, which seals off production from natural fractures and other permeable sources that are not in direct contact with the perforations (Snyder and Seale 2011).

Learning From the First Multistage Completions

From the perspective of components and system layout, the Argentine completions have been identical to those in the major shale and tight plays in Canada and the US. Packers Plus has installed 30 openhole, multistage fracturing systems in the Argentine Neuquén Basin. All have used the company’s StackFrac HD system, which allows the completion of as many fracture stages as needed in a single system, shortens stage lengths, and allows longer laterals.

The advantages seen in completing these wells with openhole, multistage fracturing technology have included the elimination of downhole cementing and perforation operations and their related wellsite equipment. The ability to fracture wells faster has also been beneficial, in light of the limited availability of pumping equipment at this point in the Argentinean plays. When equipment becomes available, several wells drilled from the same pad or in close proximity can be fractured as a group in a short time, thereby maximizing equipment usage.

The challenges and lessons learned from these initial wells in the Vaca Muerta are central to the development of future production strategies for the formation. The following lessons point to best practices in driving such an effort.

Lesson One: For proper fracturing operations, borehole geometry and condition should be confirmed before installation of the equipment.

From an operational perspective, the application of reamer runs to prepare the wellbore has become standard practice to ensure successful openhole, multistage system installation. The reamer assembly is run to total depth (TD), the wellbore is circulated for optimum cleaning, and a short trip is made from the casing shoe to bottom. If no tight spots were encountered in the last trip, the assembly is pulled out of the hole and the system installed.

Lesson Two: Ensure that innovations, processes, and procedures are understood technically, as well as linguistically, by the local workforce. Argentina had already successfully field tested openhole, multistage fracturing system technology before the Vaca Muerta came to prominence. The local industry is open to innovation that can increase production and recovery, as long as people understand the technical factors.

Lesson Three: Shale plays mean big returns, but they require substantial investment compared with conventional oil and gas projects. A clear difference between fracturing operations in tight formation plays, such as shale and other settings, is the size of the location. The surface areas of conventional development locations areas are too small to host the amount of heavy materials and related equipment required to pump and fracture a well, which typically needs thousands of pounds of proppant as well as hundreds of barrels of liquid. For unconventional development, the space required is even greater. Millions of pounds of proppant are needed, along with thousands of barrels of fluid. If space is insufficient, it may be hard to optimize logistics because equipment is placed farther from the wellsite.

The Argentine shale play is in its early stages, and operators have identified the lack of sufficient proppant, water, and space on location as the main obstacles for ensuring optimal development. Full realization of the Vaca Muerta’s potential will require the development of several key areas. International and local investment will be necessary if the play is to reach the infrastructure capacity seen in areas such as the Bakken. In Argentina’s tight sandstone formations, limitations exist but they are less formidable because the volumes and tons of material needed are lower.

A Path to the Future for Argentine Oil and Gas

From a production perspective, results from the openhole completed wells in the Neuquén Basin are not publically available. However, as the experiences from North American shale plays have proved, cost reductions and production enhancements with openhole, multistage technology have been achieved. For example, Snyder and Seale (2012) demonstrate in a comparison of production data from cemented and uncemented wells in the two core areas of the Pennsylvania Marcellus Shale that cumulative production from wells completed with the openhole, multistage fracturing method was as much as 84% higher than wells completed with the cemented liner plug and perf method. In addition to achieving better long-term recoveries, openhole, multistage completions are a safer, more efficient use of resources and intrinsically use good fracturing practices, such as reduced proppant overdisplacement and immediate flowback (Themig 2010).

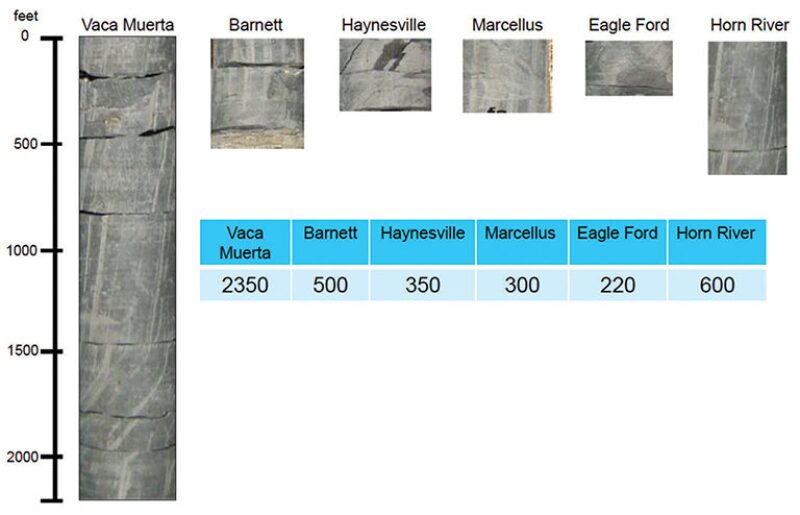

An Argentinean operator recently indicated that its production results have validated the theory and simulations that show that a vertical well with four fractures can produce similarly to a horizontal well with 25 fractures in comparable fields in the US. One of the biggest differences favoring the development of Vaca Muerta is formation thickness. Fig. 3 shows that the Vaca Muerta ranges from 4 to 10 times thicker than North American shale formations.

In tight sandstone production, openhole, multistage fracturing has also shown successful results. Several companies are planning to use openhole, multistage fracturing in these types of formations to maximize pumping equipment usage, reduce the time needed to finish the well, and increase production.

So what is next? The Vaca Muerta only recently made a transition from vertical to horizontal wells and the production results are under evaluation. This transition poses challenges that the Argentinean industry is trying to resolve, primarily involving the logistics and supply chain required to capitalize fully on the benefits of producing the Vaca Muerta. Whether horizontal or vertical wells are the best way to produce the Vaca Muerta remains to be seen. Some field results have shown that wells do not require stimulation to produce, but history and experience strongly suggest that fracturing is the most viable method for achieving adequate production across a shale play.

In summary, the Vaca Muerta has the potential to be a major shale play, possibly the world’s next big unconventional play, and the technology to accomplish it is already on the ground.

References

- Snyder, D. and Seale, R. 2012. Comparison of Production Results from Openhole and Cemented Multistage Completions in the Marcellus Shale. Paper SPE 155095-MS presented at the SPE Americas Unconventional Resources Conference, Pittsburgh, Pennsylvania, 5–7 June. doi: 10.2118/155095-MS.

- Snyder, D.J. and Seale, R. 2011. Optimization of Completions in Unconventional Reservoirs for Higher Ultimate Recovery. Paper SPE 142729-MS presented at the SPE Middle East Unconventional Gas Conference and Exhibition, Muscat, Oman, 31 January–2 February. doi: 10.2118/142729-MS.

- Themig, D. 2010. Advances in OH Multistage Fracturing Systems—A Return to Good Frac-Treatment Practices? J. Pet. Tech, 62 (5): 26–29.

- YPF. 2012. Form 6-K, Sociedad Anonima–YPF, 8 February.