Managed-pressure drilling (MPD) has been used in Vietnam since 2007 to address a number of drilling and reservoir challenges. The main application of MPD has been to overcome the challenges of granite-basement, fractured and vugular carbonate, high-pressure/high-temperature (HP/HT), and overpressured clastic reservoirs. This paper examines the procedural approaches of MPD, including constant bottomhole pressure (CBHP), equivalent-circulating-density (ECD) management, early kick detection, and pressurized-mud-cap drilling (PMCD).

MPD Techniques and Applications

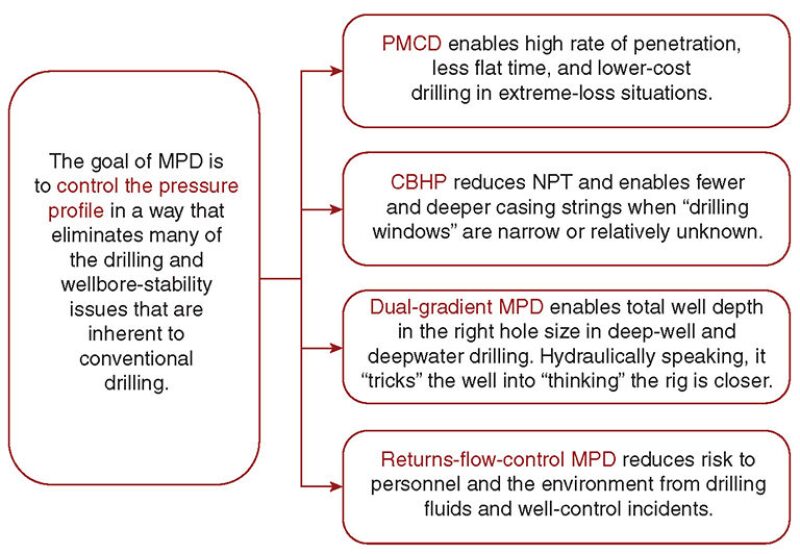

The International Association of Drilling Contractors (IADC) defines MPD as “an adaptive drilling process used to precisely control the annular pressure profile throughout the wellbore. The objectives are to ascertain the downhole pressure environment limits and to manage the annular hydraulic pressure profile accordingly. MPD is intended to avoid continuous influx of formation fluids to the surface. Any influx incidental to the operation will be safely contained using an appropriate process.”

MPD Variants

The definition of MPD covers a wide range of variations and applications, but the most commonly used among them are the PMCD and CBHP variations (Fig. 1).

PMCD as defined by the IADC as “a variation of MPD that involves drilling with no returns to surface and where an annulus fluid column, assisted by surface pressure [made possible with the use of a rotating control device (RCD)], is maintained above a formation that is capable of accepting fluid and cuttings. A sacrificial fluid with cuttings is accepted by the [lost] circulation zone. This technique is applicable for cases of severe [lost] circulation that preclude the use of conventional wellbore construction techniques.” The PMCD variant of MPD allows conventional drilling operations until losses are experienced and has been used successfully to drill through fractured and vugular carbonate formations where circulation losses can be simultaneously sudden and severe. This allows drilling to target depth despite massive losses being encountered.

The CBHP variant of MPD involves the ability to maintain a constant bottomhole pressure (BHP), especially when drillpipe connections are made and the rig mud pumps are turned off. In this instance, the MPD system exerts a backpressure value that corresponds to the frictional pressure loss. This backpressure is slowly relieved once the connection has been completed and the rig mud pumps resume operation. However, given the sophistication of current MPD-control systems, BHP not only can be kept constant but also can vary to ascertain the downhole-pressure-environment limits and allow drilling personnel to manage the annular-hydraulic-pressure profile accordingly, thereby making the drilling operation more effective and more efficient.

HP/HT; Overpressured Formations With Low Rates of Penetration; Formations With a Very Tight Kick/Loss Profile

For these applications, CBHP and early-kick-detection procedures are used with an RCD and autochoke system, coupled with a Coriolis meter and microprocessor. MPD enables a constant BHP to be maintained while drilling an HP/HT well, thereby reducing nonproductive time (NPT), especially across pressure ramps where kick/loss situations are common, time consuming, and expensive. Benefits associated with the system are early kick detection, better well control, and ease of circulating kicks out, allowing the well to be drilled through very tight kick/loss margins with quick adjustment to desired BHP. The dedicated choke allows maintaining BHP at a constant value or range.

PMCD Used To Drill Fractured/Karstified Carbonate and Granite-Basement Formations With High Fluid-Loss Rates

PMCD is implemented on wells to address severe lost circulation and hydrocarbon-influx problems when drilling through karstified/fractured limestones and granite basements. PMCD rig-up will allow safe drilling ahead without delay if significant losses are encountered. PMCD can help achieve well objectives (time, depth, costs, safety, and environmental) where high loss rates lead to problems with well control, hole cleaning, and high fluid costs. Using PMCD with a low fluid weight enables ECD to be managed, fluid losses to be minimized, and rates of penetration to be increased.

Implementation of PMCD To Manage Fluid Losses in Granite-Basement Drilling

In the past, a dependency on high brine consumption because of losses in the fractured basement for wells drilled for Hoan-Vu joint operating company resulted in very high brine and salt costs. This led to suspension of the operation because of an interruption in brine and salt supply, caused by bad weather and exhaustion of onshore supplier stocks, resulting in the total planned depth not always being achieved. Use of seawater as the drilling fluid, common in the granite basement in Vietnam, was not possible because of the slightly overpressured reservoir.

The MPD system was identified as a possible solution to the brine-management and kick/loss-on-connection problems for several reasons:

- High loss rate when drilling the fractured granite reservoir

- Brine-supply difficulties during the northeast monsoon season

- Previous experience of drilling disruption while waiting on brine

- High mud weight to control kick/loss, leading to ECD issues while making/breaking connections

The objectives of using MPD were to minimize the dependency on brine during drilling and tripping operations on the fractured granite basement and to reduce the overall amount of brine lost during these operations.

Implementation of MPD To Manage ECD in an HP/HT Overpressured Clastic Formation With Low Rate of Penetration

The Hoang Long Joint Operating Company in Vietnam planned to drill a second offshore appraisal well in the Te Giac Den field offshore Vietnam. In the first well, TGD-1X, hole instability was addressed by increasing mud weights, which increased losses.

For the later well, TGD-2X, the major objective for using MPD was to manage BHP (remove ECD fluctuations). The MPD equipment will also allow conducting CBHP operations on the 14½- or 14¾-in. and the 8¼-in. sections.

Losses During Drilling. The use of MPD means drilling with minimal overbalance. This will reduce the chance of losses.

Instability During Drilling. The use of MPD to keep BHP as close to constant as possible will reduce cyclic stresses on the formations drilled. Additionally, if splinters or cavings are observed in the cuttings, the use of MPD means that increased pressure on the wellbore can be applied instantly, thus stopping pressure-induced instability much faster than could be achieved by increasing mud weight.

Drilling Summary. Use of MPD has clearly shown results that saved rig time and minimized unplanned well-control events and NPT. By use of CBHP, drilling expectations were met and exceeded in Well TGD-2X. The MPD setup with RCD and semiautochoke manifold was the most efficient way to reduce the cost of drilling the HP/HT TGD-2X well. The previous well incurred four sidetracks. The MPD choke manifold was used to enable tripping with surface pressure. The well was then stabilized by maintaining a constant BHP. A drilling summary includes the following:

- Reduction of the mud weight during drilling facilitated by the RCD was successful in reducing the losses.

- The maximum pressure seen on the RCD (choke pressure) was 300 psi during tripping in the 12¼×14¾-in. section and was 1,254 psi in the 8¼-in. section.

- The CBHP hookup was efficient for the purpose of reducing mud weight and holding the appropriate surface backpressure (choke pressure) on connections to replace the lost ECD increment when drilling.

Implementation of MPD, Early Kick Detection, and CBHP in HP/HT Well With Very Narrow Kick/Loss Tolerance

MPD was used on this project for the following reasons:

- Narrow margin between pore and fracture pressure would require CBHP control to avoid unnecessary kick/loss incidents during dynamic and static conditions.

- Using a closed-loop MPD system in a narrow pore-pressure/fracture-gradient window would allow wellbore breathing or ballooning to be readily identified.

- Frequency of well-control incidents is higher in HP/HT wells, and the MPD manifold enables easier control of kicks.

- The MPD manifold allows kicks to be circulated at full pump rates with pipe vertical and with rotational movement.

Project Results and Conclusions

MPD was deployed on all but one of the wells drilled to date on the Moc Tinh platform (Fig. 2). The Bien Dong drilling team employed strict, well-planned, thoroughly engineered and defined HP/HT procedures and practices, successfully avoiding incidents commonly accompanying such severe HP/HT formations. Only some ballooning and minor influxes were encountered. MPD was used in the early-kick-detection mode but not in the CBHP mode.

Conclusion

Over a fairly short span of time, MPD technology has been introduced and accepted into drilling operations in Vietnam to address a range of drilling challenges, with generally good success in reducing drilling time, NPT, and cost.

Some wells were previously unable to reach their targets without the use of MPD technology.

The technology will grow in use in the various basins in Vietnam, as the wells become ever more challenging when more-difficult reservoirs and formations are drilled. These will include deepwater projects, which are in their infancy, but currently growing in number.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper SPE 165775, “Managed-Pressure Drilling—A Solution for Drilling the Challenging and Undrillable Wells in Vietnam and Southeast Asia,” by Ben Gedge, SPE, Harpreet Kaur Dalgit Singh, Elsofron Refugio, and Bao Ta Quoc, Weatherford Asia Pacific, and Nguyen Viet Bot, PVD Well Services, prepared for the 2013 SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, 22–24 October. The paper has not been peer reviewed.