A successful field trial in which foam was used as a gas-injection conformance enhancer was implemented in the Cusiana field in Colombia. An extensive front-end loading (FEL), including chemical-product screening, studying foam stability at reservoir conditions, coreflood experiments, reservoir modeling, and careful selection of well candidates, was executed for this pilot. The treatment was performed in a gas-injection well in the northern part of the field that had already attained a high recovery factor (RF) with high levels of gas recycling. The operation was performed by use of a surfactant-alternating-gas (SAG) method.

Introduction

The Cusiana field is in the foothills of the Eastern Mountain chain in Colombia, and initial production was in 1994. The field comprises three stacked reservoirs (Mirador, Barco, and Guadalupe) and two fluid systems (both volatile oils) with a rich-gas cap at near-critical conditions (pressures and temperatures greater than 5,000 psia and 250°F, respectively). The initial in-place volumes were 1.5 billion STB of oil and more than 3 Tcf of gas, with the Mirador formation containing approximately 60% of the total fluid. Development strategies have included natural depletion, gas recycling, water injection, and gas-injection redistribution. Gas recycling and redistribution provided the best recoveries.

The Mirador reservoir is a low-porosity quartzarenite with significant heterogeneities in permeability, both vertically and areally. The reservoir was developed with extensive gas reinjection, beginning in the early days of production with the gas-injection wells updip on the structure. This strategy proved beneficial from the very early stages of gas injection with regard to efficient first-contact miscibility and the favorable location of the injectors. The result has been RFs greater than 50% for most of the Mirador units. After approximately 10 years of gas reinjection, high levels of recycling were observed as a result of reservoir heterogeneities and a less-efficient gas-enrichment process because of the decrease in reservoir pressure below the minimum miscibility pressure. Those conditions led to unrecovered oil in areas that are difficult to access, such as the oil rim between the producers and the aquifer, poor-quality rock layers, and bypassed areas between the producers and injectors.

The foam-injection project for the Mirador formation was designed with two injection cycles aimed at improving the vertical conformance of the gas at the injection well and the sweep efficiency deep into the reservoir. Conceptually, the foam treatments should perform similarly to a gas-injection-redistribution project (i.e., convert producers to gas injectors) but with a smaller associated benefit. The complete paper details the FEL process used to start the field trial, the field operation for the first cycle, and the results obtained. The second cycle in the same well is planned for 2013, and foam-enhanced-oil-recovery (EOR) pilots in nearby fields are in planning stages.

FEL

This project started in 2006 with the screening of foaming surfactants for the high pressure and temperatures to be used in the well-stimulation and EOR projects. For this pilot, an extensive FEL including chemical-product screening, foam stability at reservoir conditions, coreflood experiments, and mechanistic reservoir modeling, and a careful selection of reservoir areas and well candidates was performed.

Chemical (Surfactant) Selection. As part of the assurance process to propose this technology, several stages of laboratory evaluations were performed between 2006 and 2009. Benchmarking surfactants was performed by testing parameters such as compatibility with reservoir fluids and stability at 180°F and atmospheric pressure for a wide range of concentrations.

In 2010, additional products were screened and it was found that an alpha olefin sulfonate surfactant (i.e., carbon-chain length of C14–C16) was the best performer, even at very low concentrations (<0.2 wt% active component). The selected product showed good tolerance to the presence of biocide and oil and a low adsorption when tested on the Mirador rock. This type of surfactant is a commercial product that has been used in other foam-injection projects, including the Snorre field in the North Sea.

Coreflooding Results. Several coreflooding experiments at low and high pressures and temperatures were performed to prepare for the Cusiana and other foam pilots. The experiments were performed with dead reservoir fluids and different kinds of rock, including Berea, sandpacks, matrix-dominated Mirador (Cusiana), and fracture-dominated Mirador (Rio Chitamena). The results obtained in open-fracture core samples in 2006 showed incremental recoveries between 10 and 17%. These results motivated additional foam-injection tests in different systems. The results obtained in individual homogeneous cores and sandpacks consistently showed incremental recoveries between 6 and 8% of the stock-tank oil in place.

Reservoir-Area and Well Selection. The selected reservoir area for the first foam pilot in Cusiana was the northern part of the field, where a mature gas injection has been in operation for 10 to 12 years. A high RF (>50%) has been attained with high levels of gas recycling. A contrast in gas/oil ratio (GOR) was observed between the different flow units of the Mirador formation. One of the lower flow units (Mir-VI) dominates injection and production because of its higher permeability, and it has the highest level of recycling. The main objective of the project was to block this unit, forcing injection into the upper Mirador units to improve the sweep efficiency and obtain additional oil recovery. Well CS R-11 was selected. It was a producing well that was converted to gas injection in 2006, and it has shown clear communication with at least three oil producers (CS R-9ST1, CS Q-4ST2Y, and CS Q-17). It is important to note that one of the criteria to select the pilot area/well was to minimize exposure to losses in production in case of failure, while guaranteeing the applicability of the technology.

Field Deployment

The SAG method was used to implement the treatment selectively in the Lower Mirador by use of coiled tubing and a downhole packer to isolate the Lower Mirador from the Upper Mirador and to provide treatment selectiveness. It required vast operation logistics to intervene in a deep well with high pressures and temperatures while maintaining the best health, safety, and environmental practices and integrity standards.

After the well was killed safely, 5,400 bbl of surfactant-foamer solution at 0.2 wt% was pumped into the Lower Mirador units through the coiled tubing. This main treatment was followed by a small batch of nonfoaming low-interfacial-tension solution to displace the entire foaming treatment into the reservoir and avoid foam formation at the wellbore. This stage was followed by a high-rate-injection period (>100 MMscf/D) to promote foam generation in the reservoir. After 2 days, the well was returned to its normal gas-injection rate of approximately 35 MMscf/D.

Monitoring Plan. As part of the job design and operation, an intensive monitoring plan was followed.

- Baseline well tests in the oil producers

- Continuous wellhead-pressure/-temperature records in the injector and the producers

- A sequence of injection-profile logs (IPLs) in the gas-injection well to monitor changes in the injection profile

- Well tests taken 2 weeks after the treatment and every month afterward and a production-profile log in the closest oil producer (Well CR R-9ST1) after the effects of foam injection were observed

Results

The first cycle of foam treatments was implemented in Well CS R-11 in November 2011, with the objective of changing the vertical injection conformance of the well. The following observations support a successful treatment.

- The wellhead pressure, after the well returned to the base injection rate, increased by approximately 200 to 300 psia, indicating a significant reduction in well injectivity.

- The post-job IPL showed a different gas-injection profile, with the Mir-VI unit’s share decreasing from 49 to 17%. Additional IPLs run in Well CS R-11 in December 2011 and in April 2012 showed that the foam was still partially blocking gas injection into the Mir-VI unit. The injectivity has increased gradually in this layer.

- The oil rate increased (or there was an attenuation in oil declination) 2 to 3 months after foam injection and the GOR declined in the three affected wells (CS R-9ST1, CS Q-4ST2Y, and CS Q-17).

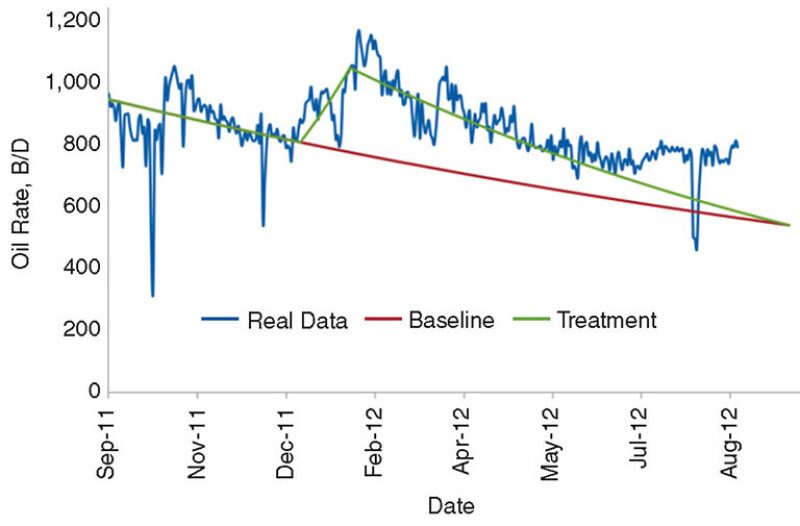

The incremental recovery for the entire pilot (two cycles) was estimated to be between 0.01 million and 0.05 million STB (most likely 0.03 million STB), assuming different trends in production decline for the affected oil producers. The evaluation of benefits from the first cycle showed that the affected producers experienced a temporary increase in production that started soon after the foam treatment, reached a maximum, and then started declining again to reach the baseline projection after several months (this time frame depends on the durability of the foam’s blocking effect and the distance from and connectivity to the treated injector (estimated time for the Well CS R-11 first cycle was approximately 9–10 months). The ramp up observed in the producers corresponds to the period in which the gas was forced into new flow paths in the reservoir as the foam forms and blocks the higher-permeability layers and corridors. Fig. 1 shows that the benefit from the first cycle was 0.031 million STB. The benefit forecast for the second cycle is 0.025 million STB, which means that the pilot is performing according to the upside estimation.

Conclusions

- Operational feasibility of implementing foam-EOR projects in Cusiana gas-injection wells was confirmed. Overall deployment of the SAG strategy has been successful.

- The foam’s gas-blocking effect and divergence in the near-wellbore region was achieved as expected.

- The well recovered its total injectivity relatively soon (approximately 2 weeks) after the treatment, and maintained the gas divergence.

- The risk of blocking 100% of the injectivity of the treated zones is very low, and treatments do not have to be selective.

- On the basis of the observed response in the affected oil producers, after approximately 2 months, improvements in sweep efficiency, deep in the reservoir, could be inferred.

- There are opportunities to simplify the deployment by avoiding selectiveness, which would improve the economic value of the project.

This article, written by Senior Technology Editor Dennis Denney, contains highlights of paper IPTC 16984, “Successful Foam-EOR Pilot in a Mature Volatile-Oil Reservoir Under Miscible-Gas Injection,” by A. Ocampo, A. Restrepo, SPE, H. Cifuentes, SPE, J. Hester, N. Orozco, C. Gil, and E. Castro, Equion Energia, and S. Lopera and C. Gonzalez, Universidad Nacional de Colombia, prepared for the 2013 International Petroleum Technology Conference, Beijing, 26–28 March. The paper has not been peer reviewed. Copyright 2013 International Petroleum Technology Conference. Reproduced by permission.