For operators and service companies looking to gain an edge in a growing technology marketplace, the link between technology development strategy and overall operational strategy is fundamental. Careful planning is required to ensure the efficient use of resources on technologies that target high-priority problems and high-impact solutions, while responding to near-term challenges and laying the foundation for longer-term goals. An established roadmap could serve as a point of reference to satisfy technology requirements in response to current and arising challenges for a company looking to produce new technologies in-house or facilitate the development with other companies.

With that in mind, the Abu Dhabi National Oil Company’s (ADNOC) Upstream Directorate developed a stage-gate process for new technology development and qualification. The process was designed to minimize the risk associated with deploying new technologies to a level that can be managed or mitigated, ensuring compliance with operational constraints and promoting the safety of assets and people.

Sherif El-Gharbawy, ADNOC’s authority on technology maturity, presented a paper outlining case studies on the development and qualification process, Tech Qual, at the 2017 Offshore Technology Conference (OTC). At last year’s OTC, he presented a paper with coauthor, Wafik Beydoun on the establishment of ADNOC’s technology development process. That paper outlined the company’s use of Technology Readiness Levels (TRLs) to advance the development of a new, or unproven, technology along a structured path toward deployment or commercialization.

Developed by NASA in the 1980s to help qualify spacecraft design, the TRL is a means of estimating the readiness of a component to be implemented into an operating system. The process involves the establishment of stage gates to facilitate the transition of the technology from one phase to the next while staying focused on applicability and profitability.

“[The NASA TRL Scale] is the original scale and most-recognized scale, both globally and regionally in the Arabian Gulf area,” El-Gharbawy said about ADNOC’s adoption of TRLs. “It was made simpler and adapted to fit our operations terminology and technology development phases as opposed to NASA’s flight simulation applications.”

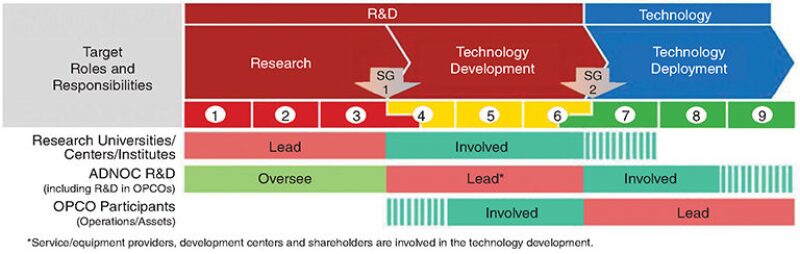

ADNOC Research and Development manages the progress in TRLs 1–6 (Fig. 1) before transferring those responsibilities to its operating companies (OPCOs). Along with the research and development teams from its OPCOs, service companies, and international shareholders, ADNOC leads the technology development phase between TRLs 4 and 6, with the OPCOs taking ownership afterward. The goal is to steer the development process away from the “Valley of Death,” a term used to describe a technology’s failure to reduce risk through development, and hence bridge the gap between fundamental research in the lower TRLs and commercialization in the higher TRLs.

“The Valley of Death is where many technology developments fail because it is the verification phase where the proposed new technology is rigorously put through laboratory or numerical testing,” El-Gharbawy said. “Additionally, the technology’s return on investment is thoroughly evaluated through stage gates, and only technologies with positive NPVs [net present values] are allowed to pass through TRL 6.”

The first step of roadmapping involves the establishment of corporate strategy highlights, as well as the identification, consolidation, and prioritization of technical challenges facing OPCO operations. The next step is finding commonalities between the challenges OPCOs face and ADNOC’s strategy and the establishment of what El-Gharbawy et al. termed the “corporate technology toolbox baseline.”

ADNOC Research and Development is also developing an induction process to import the tools and technologies identified by its roadmap, which will outline the pathways for OPCOs to meet their targets for increasing efficiency, performance, and profitability.

The Tech Qual comprises three evaluations:

- Strategic/operational impact evaluation. An examination of the alignment of new technology with the company’s business strategy and OPCOs’ technical challenges.

- Technical evaluation. The assessment of the feasibility, maturity, and alignment of the technology with regard to technology development portfolios.

- Business evaluation and commercialization potential. The comparison of resource investment with the expected return on that investment, as well as the effect of intellectual property roadblocks that may come in the way of commercializing a technology.

El-Gharbawy et al. wrote that a central element of Tech Qual is the development of risk analysis and mitigation measures agreed upon by appointed cross-functional team members. Tech Qual has been submitted to management for endorsement at the group level. The process has been vetted and pilot-tested through the completion of five technology qualifications in stage gates 1 and 2. El-Gharbawy said the next step with the process would be to deploy it for all new technologies.

Tech Qual Case Studies

El-Gharbawy outlined various test cases of technologies developed either within the ADNOC Group or in partnership with service companies. Spanning different intervals of the TRL scale, these technologies were qualified by cross-functional teams of subject matter experts who ensured their strategic alignment with the roadmap and the operational challenges to be remedied.

Manara Smart Completion System. Manara is an intelligent completion system from Schlumberger designed to provide permanent downhole monitoring and real-time in-lateral flow control within multiple zones and compartments.

The technology provides in-situ measurements of pressure, temperature, flow rate, and water cut across a formation face in each zone of a lateral. It consists of an electric-motor-driven, infinite-position interval-control valve, and an integrated downhole monitoring package. A single control line connecting stations to each other and to the surface minimizes the need for wellhead penetrations. The elimination of an additional control line across the connection between the two sections of a completion allows the lower completion to be run in on drillpipe. Combined with a surface software module, the system could minimize the need for rigless intervention for reservoir monitoring.

ADNOC’s strategic/operational impact evaluation found that deployment of the Manara system would be in accordance with the company’s reservoir management guidelines for achieving flow allocation and control when commingling production from different reservoirs. El-Gharbawy et al. wrote that it could potentially deliver significant estimated cost savings by minimizing the number of required production logging tool (PLT) runs. The company estimated that the savings from reduced PLT runs would compensate for the initial investment in the system, delivering an overall cost reduction of approximately USD 0.25/BOE. In its technical evaluation, Manara was rated as a highly feasible enhancing technology at TRL 6.

“This is a very useful tool for reservoir management, and is technically qualified,” El-Gharbawy said. “There are similar technologies [commercially available] but they do not offer the exact application of Manara.”

The risk analysis of the Manara system showed that its primary strategic risk was a possible inability to meet ADNOC’s guidelines for production allocation from different reservoirs, which could result in an unexpected increase in PLT runs and a loss or an inability to meet production targets. A detailed technical evaluation and risk analysis will be performed with Schlumberger as part of a pilot preparation.

Real-Time Online Black Powder Detection Device. ADNOC’s Petroleum Institute (PI) developed a real-time system for monitoring gas flow in pipelines and detecting black powder, a mixture of contaminants (including iron sulfide, iron oxide, and iron carbonate). Black powder can have a corrosive effect in distribution systems. As the particles flow within a pipeline, they accumulate around control valves, compressors, and other equipment, potentially causing pressure drop and unexpected shutdowns.

First proposed in a 2014 paper, the device uses near-infrared, mid-infrared, and Raman spectroscopy to analyze the reflected, transmitted, and refracted waves that interact with target particles. Al Hosani et al. argued that, because light in the infrared range has a different absorption rate for different constituents of black powder, knowledge of the spectrum of each constituent can lead to good estimations of where they will concentrate.

El-Gharbawy said that was an example of a technology developed in-house, fitting in line with the company’s overall strategy.

The black powder detection device is currently at TRL 6 and the company is working to develop a trial in actual field conditions. After successful pilot deployment, ADNOC will develop a commercialization and marketing plan for the device. Commercialization may be achieved through a licensing agreement with one or more companies, or by creating a startup company for manufacturing and supply. However, in its risk analysis the company identified a major strategic risk: a change in strategy on black powder monitoring resulting in a lack of interested buyers of the technology. They found that certification of the device at the required fire rating mitigates any safety hazards associated with device ignition.

For Further Reading

OTC 27058 Technology Qualification for the ADNOC Group Operations in the Arabian Gulf by S. El-Gharbawy and W. Beydoun, ADNOC.

OTC 27558 Piloting the ADNOC Group Process for New Technology Development and Qualification by S. El-Gharbawy, ADNOC; W. Beydoun, TOTAL Kuwait et al.

Al Hosani, E., Meribout, M. et al. 2014. A New Optical-Based Device for Online Black Powder Detection in Gas Pipelines. IEEE Transactions on Instrumentation and Measurement. 63 (9): 2238–2252.