Recent headlines declared that the United States could end net oil imports by 2037.That finding, by the US Energy Information Administration (EIA), is the agency’s first-ever projection—albeit under a high-resource scenario—of possible oil self-sufficiency for America.

It is a stunning reversal of a trend. US net oil import dependency was at 60% as recently as 2005 and thought to be headed to 70% within a decade. Instead, today it is about 33% and dropping.

Many of my colleagues in the oil and gas industry and I have long believed that achieving such a milestone was possible, if only the right combination of technology, economics, and political will could come together. We understood the scope of the vast untapped hydrocarbon bounty in the US, recognizing that half of its identified oil endowment of nearly three-quarters of a trillion barrels of oil is untapped. That is why the US leads the world in the application of improved oil recovery (IOR) and enhanced oil recovery (EOR) technologies.

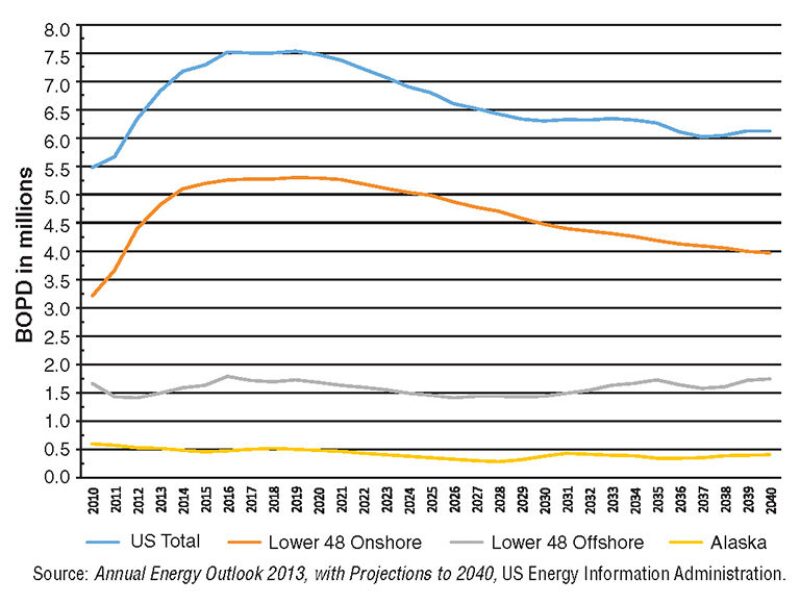

Much of the credit for the surge in US oil production goes to the advances in horizontal drilling and hydraulic fracturing applied to massive shale and other tight oil rock formations. Indeed, even under the EIA’s reference case, shown in Fig. 1, tight oil sustains overall US production for many years at a level nearly twice what expectations were just a decade ago. Both technologies essentially qualify as IOR, bolstering the claim that, in fact, IOR is responsible for America’s energy revolution.

EOR’s Role

There is another component of the IOR umbrella that for now is overshadowed by the fracturing/horizontal drilling boom: EOR.

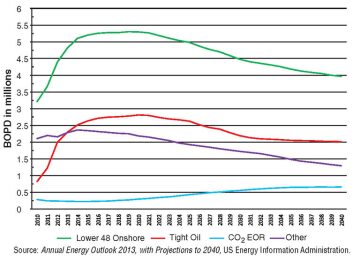

Fig. 2 shows that EOR, in particular carbon dioxide EOR flooding, will continue to gain market share in the US oil production mix to 2040 and even grow at an annualized rate double that of tight oil output in that forecast. EIA’s robust forecast for CO2 EOR assumes that there will be ample supply of CO2 from anthropogenic sources, spurred no doubt by government incentives or mandates to capture industrial CO2 emissions in efforts to reduce greenhouse gas emissions.

Could the projections for both tight oil production and EOR production become enlarged when these two sectors converge?

Generally speaking, the typical recovery factor (RF) for conventional oil reservoirs is about 30% to 40% under primary and secondary recovery combined. Incorporating advanced IOR methods and EOR can push that RF to as much as 40% to 50%.The RF for tight oil reservoirs, based on US shale production experience, can range from 3% to 7% of the original oil in place, with outliers being as low as 1% or as high as 10%. The US tight oil resource is vast, so now is the time to think of EOR to improve recovery in tight oil reserves. What if the RF in the Bakken Shale or Eagle Ford Shale could be doubled? This will significantly change US oil production going forward.

That is why I am convinced that EOR application in unconventional oil resources is the next frontier of technology development. Even as the global energy industry is still trying to assimilate the revolutionary impact of successfully applying advanced drilling and completion technologies to these vast resources, the world’s top EOR specialists are now focusing on the next stage: how to maximize tertiary oil recovery from unconventional reservoirs.

That can be seen in an expanded profile for unconventional resources at the 19th SPE Improved Oil Recovery Symposium that was held 12–16 April 2014, in Tulsa, Oklahoma.

Unconventional Resources and EOR

For most of its existence, dating back to 1978, the conference known today as the Improved Oil Recovery Symposium has focused on traditional EOR, which includes the injection of liquids, gases, or steam in a reservoir to enhance recovery. IOR includes traditional EOR as well as other methods to improve recovery, such as horizontal wells, multilateral wells, etc.

EOR topics still dominate the IOR symposium’s technical program today. The symposium’s organizers recognize the crucial role that advanced drilling and fracturing technologies play in commercializing the unconventional plays that dominate US oil and gas activity today. That means a higher profile for these technologies in the IOR symposium. The number of papers listed under our Unconventional Resources/IOR track this year increased fivefold since the 2012 Symposium.

As new technologies increasingly contribute to improving RF in unconventional resources, I am sure that they will be included in future symposia. Indeed, the oil and gas industry already is seeing some initial research in applying true EOR methods to unconventional reservoirs, and the first commercial unconventional reservoir EOR project may not be too far off.

This will not happen overnight. Most EOR/IOR processes go through several stages, such as concept development, simulation models, reservoir studies, laboratory models, field pilot tests, and, finally, field-wide implementation. This is a challenge to our industry.

IOR/EOR Drilling Challenges

Horizontal drilling has made huge strides in recent years as a result of the unconventional resource development boom, with its market share rocketing to almost 70% of all wells drilled in the US from only about 5–6% a decade ago.

It is likely that the next advances in horizontal drilling will increase its application in EOR projects. There is yet a lot of work to be done in controlling flood fronts in heterogeneous reservoirs. This issue is especially critical for horizontal wells where the industry is trying to inject uniformly along the length of a 5,000 ft- or 10,000 ft-long horizontal lateral.

There continue to be significant technical challenges for operators and drillers in building horizontal and directional well profiles, notably technical challenges with conflicting objectives. We should be able to drill long wells. This generally requires slower build rates, i.e., a large turning radius to go from the vertical to the horizontal direction. On the other hand, a small turning radius facilitates pump installation in the vertical section, but that is still close to the heel of the horizontal well. This maximizes oil recovery by minimizing bottomhole well flowing pressure. We as an industry are still balancing these conflicting requirements.

Also among horizontal drilling technology challenges is learning how to fracture dual-lateral or multilateral wells before these practices become widely accepted in low-permeability unconventional reservoirs. While industry has greatly advanced its know-how when it comes to fracturing horizontal laterals of as much as 5,000 ft to 10,000 ft, there is only a limited track record when it comes to fracturing multiple laterals. Fractured multilaterals could bolster the economics of unconventional resource development by optimizing simultaneous production from multiple formations.

These are just a few examples of the technology challenges awaiting our industry as we embark on this exciting new frontier for unconventional oil resources with IOR and EOR.