The beneficial use of produced water is receiving great attention in the oil and gas industry. As oil and gas are produced, large quantities of water containing high amounts of total dissolved solids (TDS) are produced in the process. Most of the high-saline produced water is reinjected into disposal wells. Reclaiming produced water as the base fluid for hydraulic fracturing not only helps to alleviate the industry’s dependence on fresh water, but also lowers the overall cost of the fracturing treatment.

Contents of Produced Water

Produced water usually comprises the formation water and the injected fluids from previous treatments. It can contain hydrocarbons, high levels of TDS, suspended solids, and residual production chemicals. The use of produced water for hydraulic fracturing has many advantages, such as reduction in disposal of produced water, reduction of freshwater consumption during completion and production operations, and realization of economic benefits by the operator. If produced water is gathered at or near the production site and a minimal treatment is applied in hydraulic fracturing fluids, recycling and reuse programs may become economically and environmentally beneficial.

As hydraulic fracturing in shale plays continues to require large amounts of fresh water for oilfield operations (i.e., 4 to 6 million gallons per well in some cases), reusing produced water reduces freshwater consumption. With increased restrictions on water availability from subsurface or surface sources, fresh water is becoming more difficult to obtain.

In some basins, the use of produced water in oil and gas drilling and slickwater-based fracturing treatments has been explored. Typically, these applications use water with low TDS levels. Little work has been done on the use of produced water with high TDS levels (>200,000 ppm) in fracturing fluids designed with linear or crosslinked gel bases.

Treating High-TDS Water

To reuse high-TDS produced water effectively in crosslinked gel-based hydraulic fracturing fluids, the water must first be treated. The treatment need not generate potable or fresh water, as some oil and gas industry water treatments do. The goal of the treatment is to remove only minerals that hinder the development of the crosslinked fluid or that cause scale buildup in the well. One effective form of produced water treatment is electrocoagulation (EC).

In EC, an electric current is applied across metal plates to remove various contaminants from the water. Heavy metals (ions) and colloids (organics and inorganics) are primarily held in solution by electrical charges and particle size. The electrical charge applied to the solution of contaminated water destabilizes the charges on the particles and generates a coagulation reaction.

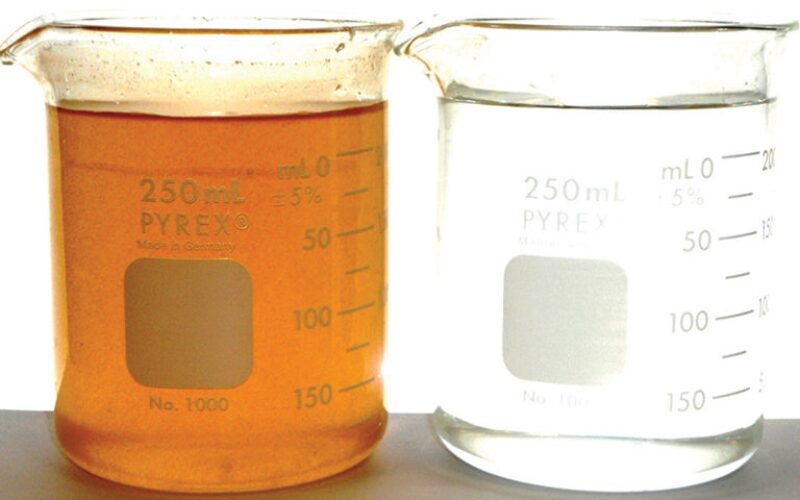

A produced water sample was treated using a bench-scale EC process. This step in the recycling program removes specific contaminants, including suspended solids, which allows the treated water to be used in future fracturing applications. Fig. 1 shows a visual comparison of produced water samples, one untreated and the other treated. In the EC treatment, the suspended solids are concentrated into a waste stream that accounts for 3% to 5% of the total volume. This waste stream can be reduced further by approximately 90% through the use of a filter press. This step enables the removal of the dry solids and the filtration of the water, which is returned to the EC treatment stream.

Scaling Tendencies

Produced water can contain high levels of scaling ions such as barite, calcite, and siderite. It is important to reduce these ions, when cost-effective, and control the scale, when ion removal is not economic. This requires predicting scaling tendencies and developing a scale inhibitor suitable for use in fracturing fluids.

The Pitzer theory of electrolytes calculates the scaling potential of water over a wide range of temperatures, pressures, TDS, and cosolvents. A scaling model based on the Pitzer theory can be used to assess the scaling tendency of produced brines under the temperatures and pressures of a potential fracturing treatment.

EC is very effective in removing total suspended solids, turbidity, oil and grease, and heavy metals, i.e., copper, zinc, lead, arsenic, chromium, and iron. The removal of heavy metals and the reduction of divalent ions typically results in EC-treated produced water having lower scaling tendencies than untreated produced water. When necessary, treated produced water can be tested by use of a dynamic scale loop to determine the minimum effective dose of scale inhibitor. It is recommended that scaling tendency tests be performed before development of a fracturing fluid so that the scale inhibitor is included in the fluid analysis.

Recycle and Reuse

An effective fracturing fluid must have these characteristics: easy preparation, low fluid loss, good proppant transport capacity (viscosity), low pipe friction, efficient recovery from the reservoir, and low gel residue. Through the use of gelling agents, fluids achieve excellent viscosity. For water-based fluids, guar gum and their derivatives, such as hydroxypropyl guar and carboxymethylhydroxypropyl guar (CMHPG), can be used. The derivative guars generally have less residues and faster hydration compared with non-high-yield guars. Adding borate crosslinkers or metal-based crosslinkers, such as zirconium, titanium, or aluminum, significantly increases the viscosity of guar-polymer gels.

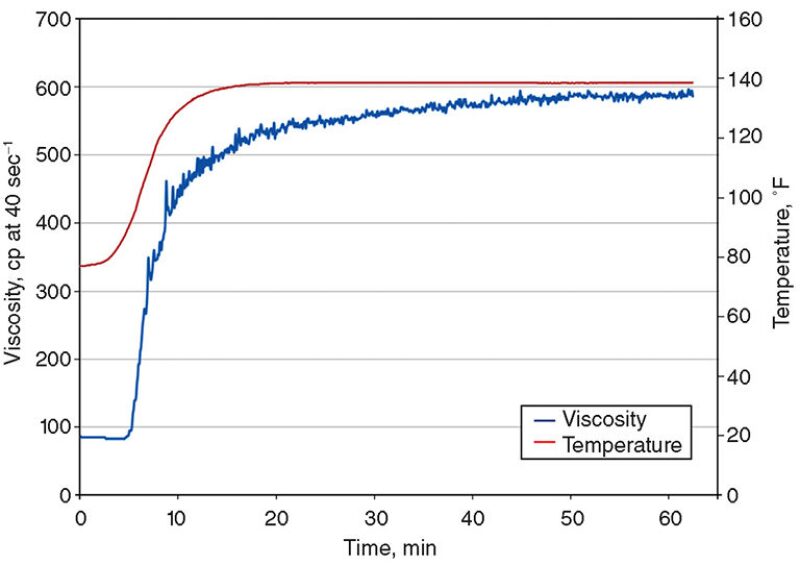

Crosslinked fluids have a greater capacity to transport proppants than uncrosslinked fluids. This transport capacity is measured by a rheometer in which fluid is tested at specific temperatures and shear rates. In these tests, it is possible to observe the transporting elastic regime and proppant settling. A minimum transport capacity of 400 cp measured at 40 sec–1 with a B2 bob is commonly desired. This value was used as a reference for fracturing fluid tests developed using the rheometer.

The proprietary fluid system used in this study is designed to hydraulically fracture a sandstone formation (~6,800 ft in true vertical depth [TVD]) in the Permian Basin. The fluid consisted of a derivative polysaccharide guar gum, a metal-based crosslinker, oxidizing breaker, breaker catalyst, and a nonemulsifier surfactant. The bottomhole temperature (BHT) tested was 140°F. As seen in Fig. 2, the crosslinked fluid with 100% EC-treated produced water retained more than the desired minimum viscosity of 400 cp for the required pump time of 60 min.

Field Trial

A field trial was performed in which seven wells with a total of 97 fracturing stages were tested using 100% EC-treated produced water. The well stimulations were performed to evaluate the validity of the laboratory test findings under field conditions in New Mexico. The sandstone formation depth was approximately 6,800 ft in TVD (11,300 ft in measured depth) with an approximate BHT of 140°F. The fracturing fluid system was a 30-lbm derivative crosslinked gel. The 30-lbm derivative crosslinked fluid was also used in the bench-scale testing.

Dynamic break tests of a 30-lbm derivative crosslinked gel with treated produced water as the base fluid were conducted in the laboratory using a Fann 35 viscometer to help ensure proper fluid rheology before stimulation. The derivative guar gum was hydrated in the treated produced water at a pH of less than 7, before an oxidizing breaker and a breaker activator were added.

The gel was crosslinked using a metal-based crosslinker at 140°F. To break the crosslinked gel on an optimal basis, the amounts of breaker and breaker activator used were adjusted. The tested fluid was designed to maintain greater than 400 cp—the minimum viscosity recommended for proppant transport capabilities—for 60 min. The fluid performed as specified in the test procedures.

One trial well was stimulated using 1.4 million gallons of treated produced fluid and approximately 1.7 million lbm of proppant placed in 17 treatment stages. The average treatment pressure was 1,911 psi and the average treatment rate was 47 bbl/min. The pump time for each stage was approximately 55 min and consisted of pad and proppant stages with an average maximum proppant concentration of 4.4 lbm/gal. No mechanical failure or screening out was encountered during the stimulation. The treating pressure trends observed were as modeled with 2% KCl water as the base fluid, indicating no adverse effects on the treatment pressure or ability to place proppant when using high-TDS treated produced water (>270,000 ppm).

Reducing Use of Fresh Water

Based on the results of the trial, it is feasible to use treated produced water with more than 270,000 ppm of TDS as the base fluid for hydraulic fracturing. The fluid performed comparably to fluid developed using fresh water as the base fluid under the same test conditions. Initial oil and gas production rates from the stimulated wells in the field trial proved comparable to, if not better than, than the production rates from an offset well.

By applying a minimal and cost-efficient treatment to the produced water and designing the appropriate fluid chemistry, the treated produced water was effectively used as a base fluid in a crosslinked application. More than 8 million gallons of fresh water were saved and more than 1,400 truckloads were eliminated in this multi-well trial, with the operator realizing a significant savings in water management costs. These results show a considerable potential for the industry to reduce its dependence on fresh water for hydraulic fracturing and, hence, reduce the cost of fracturing treatments.